JOHNSON CONTROLS

214

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

SECTION 7 - OPERATION

If the compressor speed exceeds the maximum

frequency the compressor is allowed to operate minus

1 hertz for a period of 3 minutes without bringing the

leaving chilled liquid temperature to within Setpoint

plus CR/2, the chiller control will make a decision to

start another compressor. At this point, the first com-

pressor will decelerate to a frequency of 5 Hz. Reduc-

ing the frequency of the running compressor to 5 Hz

enables the differential between discharge and suction

pressure to be reduced to a point where it will not affect

motor current when the running compressor is ramped

up. It also reduces the possibility of backspin on the

running compressor. The next lag compressor will be

activated and all compressors will be accelerated to the

START FREQ. The START FREQ is specified by the

formula:

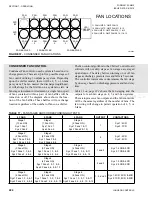

START FREQ = Current VSD Freq x (Number of Compressor enabled -1)

Number of Compressors enabled

For example: Current VSD Freq = max freq of the chiller = 200 Hz.

Number of compressors enabled = 2 = Original

compressor running, plus the compressor to be added.

In this example, assume a single compressor had

been running at the max frequency of 200 Hz without

satisfying cooling demand. (2) compressors are now

enabled when the second compressor is activated. Plac-

ing these values in the formula, the START Frequency

equals 200 Hz x (2-1)/2 equals 100 Hz. The compres-

sors will be accelerated to a start frequency of 100 Hz.

Load and unload timers will be set to 30 seconds. The

anti-recycle timer will bew set to 120 seconds.

If additional cooling is required, after the initial 30 sec-

onds of operation, loading will occur at the rate of 0.1

-1 Hz every 2 seconds, unless load limiting occurs.

If the cooling capacity exceeds the demand and tem-

perature continues to drop while in the Control Range

(CR) with multiple compressors operating, the Chiller

Control Board microprocessor will decrease the speed

of the compressor(s) at the rate of 0.1 to 1 Hz every

2 seconds until the LCHLT stabilizes within the Con-

trol Range. If frequency (speed) drops below the LESS

COMP FREQ – 20 Hz or the minimum VSD frequen-

cy, whichever is higher, the compressors will be decel-

erated to a speed of 5 Hz, the last compressor disabled,

and the remaining compressor(s) restarted minus one

lag compressor. The LESS COMP FREQ is designated

as:

LESS COMP FREQ = Max VSD Freq x (Number of compressor enabled -1)

Number of Compressors enabled

For example: 200 Hz = max freq of the chiller.

Number of compressors enabled before shutdown = 2

In this example, one compressor will be shut down

when the speed of the compressors drops to 200 Hz x

(2-1)/2 = 100 Hz-20 Hz = 80 Hz.

The restart frequency for the compressor(s) after re-

moving a lag compressor is the OFF FREQ. The OFF

FREQ is designated as:

OFF FREQ = Current VSD Freq x (Number of compressors e1)

Number of Compressors enabled

For example: 80 Hz = current freq of the chiller in the example above.

Number of compressors enabled at shutdown = 1

In the example above, one compressor will restart at

160 Hz as calculated in the formula below:

80 Hz x (1+1) = 160 Hz

1

The load timer will also be set to 30 seconds and the

unload timer will be set to 10 seconds.

On 3 and 4 compressor chillers, if frequency (speed)

drops below the LESS COMP FREQ – 20 Hz or the

minimum VSD frequency, whichever is higher, anoth-

er lag compressor will be shut down using the same

guidelines.

When the system is only operating a single (lead) com-

pressor, if temperature continues to stay below the

Control Range (Setpoint – CR) or continues to drop

while in the Control Range, the Chiller Control Board

microprocessor will unload the compressor at the rate

of 0.1 to 1 Hz every 2 seconds. This will continue un-

til the frequency drops below the Minimum VSD Fre-

quency determined by the ambient temperature. At this

point, the lead compressor will be shut down, if tem-

perature is below the Setpoint - CR.

Fuzzy Logic Control

The fuzzy logic control in software makes decisions to

increase or decrease speed according to the error or de-

viation from Setpoint, and the rate of change of chilled

liquid temperature. Before making a change in speed,

the Chiller Control Board microprocessor will look at

the load and unload timers to assure they are timed out.

It also looks to assure there is no load limiting in effect.

Each time a change is made, the incremental change in

speed is still between 0.1 and1 Hz, unless temperatures

fall near the leaving chilled liquid cutout.

In most situations, when the chilled liquid tempera-

ture is above the Setpoint plus CR, the Chiller Con-

trol Board microprocessor will continue to increase

the speed of the compressor(s) to load the chiller until

temperature drops in the general range of the Setpoint

Summary of Contents for YCIV0157

Page 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...