JOHNSON CONTROLS

211

SECTION 7 - OPERATION

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

7

The Setpoint is the Leaving Chilled Liquid Tempera-

ture midpoint of the Control (Cooling) Range. The

Setpoint High Limit is the Setpoint plus the Control

Range. The Setpoint Low Limit is the Setpoint minus

the Control Range. The chiller will attempt to con-

trol within the temperature range programmed by the

Setpoint plus or minus CR.

Starting and stopping of compressors will be handled

by the Standard or High IPLV Capacity Control Rou-

tine. Loading and unloading will be controlled by tem-

perature offset and rate by the Fuzzy Logic Control

Routine.

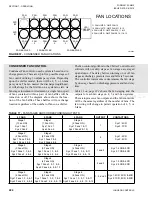

A graphical representation of the Setpoint and high and

low limit (plus or minus CR) are shown in

.

NUMBER OF COMPRESSORS TO START

General

The number of compressors to start control logic varies

between the standard and optional High IPLV chillers.

Standard IPLV chiller control utilizes sequential logic

that requires the microprocessor to start 1 compressor

at a time and only add a compressor when all running

compressors reach maximum speed. Optional High

IPLV chillers have control algorithms that provide

“smart” anticipatory control to determine how many

compressors need to be started to satisfy the current

load. The “smart” logic is capable of reducing short

cycling, and reducing loading time on a hot water start,

and starting all compressors at the same time.

Standard IPLV

The Standard IPLV control always starts a single com-

pressor under all circumstances as the first step of

loading. The Chiller Control Board does not make de-

cisions on the number of compressors to start based

on chilled liquid temperatures and prior compressor

operation when starting the chiller. An additional com-

pressor is only started when the lead compressor has

reached maximum speed and cooling requirements are

not satisfied.

Optional Optimized High IPLV

On optimized IPLV chillers, the Number of

Compressors to Start Logic will be used to determine

how many compressors should be run when the unit

starts from the all compressors stopped state. This rou-

tine will try to run all the compressors unless it is deter-

mined that less will be needed due to light load.

The first step in the sequence is for the microprocessor

to set the number of compressors to start equal to the

number of compressors in the chiller. The micropro-

cessor will look at two prior conditions relating to the

compressor operating time the previous time it ran and

how long the last compressor has been off along with

two indicators of chilled liquid load requirements (rate

of change of chilled liquid temperature and deviation

from setpoint). Temperature deviation is the amount of

error compared to the setpoint high limit (Setpoint plus

CR). Based on this information, the microprocessor

will then determine the number of compressors to start.

The flowchart in

compressor starting decision process.

It is desirable to run as many compressors as possible

for increased efficiency. Optimized logic will keep as

many compressors on line and reduce speed in an ef-

fort to optimize the use of the entire evaporator tube

surface.

48˚F --------------------------------------------------

46˚F ---------

Se CR ( Setpoint High Limit)

----------

Programmed

44˚F ----------

Setpoint

---------------------------------

Control (Cooling) Range

42˚F ----------

----------

Setpoint – CR (Setpoint Low Limit)

40˚F

38˚F --------------------------------------------------

--------------------------------------------------

FIGURE 49 -

CHILLER CONTROL (COOLING) RANGE

LD10625

Summary of Contents for YCIV0157

Page 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...