JOHNSON CONTROLS

313

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

9

SECTION 9 - MAINTENANCE

GENERAL REQUIREMENTS

The units have been designed to operate continuously,

provided they are regularly maintained and operated

within the limitations given in this manual. Each unit

should be included in a routine schedule of daily main-

tenance checks by the operator/customer, backed up by

regular service inspection and maintenance visits by a

suitably qualified Service Engineer.

It is entirely the responsibility of the owner to pro-

vide for these regular maintenance requirements and/

or enter into a maintenance agreement with a Johnson

Controls service organization to protect the operation

of the unit. If damage or a system failure occurs due

to improper maintenance during the warranty period,

Johnson Controls shall not be liable for costs incurred

to return the unit to satisfactory condition.

Section 9 - Maintenance on page

applies to the basic unit only and may,

on individual contracts, be supplemented

by additional requirements to cover any

modifications or ancillary equipment as

applicable.

Section 1 - General Chiller Information

and Safety on page 19 of this manual

should be read carefully before attempt-

ing any maintenance operations on the

unit.

Daily Maintenance

The following maintenance checks should be carried

out on a daily basis by the operator/customer. Please

note that the units are not generally user serviceable

and no attempt should be made to rectify faults or

problems found during daily checks unless competent

and equipped to do so. If in any doubt, contact your lo-

cal Johnson Controls Service Agent.

Unit Status

Press the ‘STATUS’ key on the keypad and ensure no

fault messages are displayed.

Refrigerant Leaks

Visually check the heat exchangers, compressors and

pipework for damage and gas leaks.

Operating Conditions

Read the operating pressures and temperatures at the

control panel using the display keys and check that

these are within the operating limitations given in the

manual.

Compressor Oil Level

Check the compressor oil level after the compressor

has been operating on ‘FULL LOAD’ for approximate-

ly half an hour. The oil level should be between the

upper and lower sight glasses on the oil separators.

Refrigerant Charge

When a system starts up, or sometimes after a change

of capacity, a flow of bubbles will be seen in the liquid

line sight glass. After a few minutes of stable opera-

tion, the bubbles should clear leaving just liquid refrig-

erant showing in the sight glass.

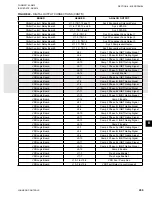

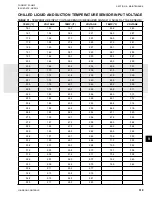

Scheduled Maintenance

The maintenance operations detailed in the following

table should be carried out on a regular basis by a suit-

ably qualified Service Engineer. It should be noted that

the interval necessary between each ‘minor’ and ‘ma-

jor’ service can vary depending on, for instance, appli-

cation, site conditions and expected operating sched-

ule. Normally a ‘minor’ service should be carried out

every three to six months and a ‘major’ service once a

year. It is recommended that your local Johnson Con-

trols Service Center is contacted for recommendations

for individual sites.

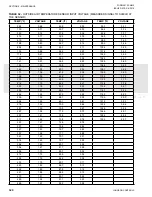

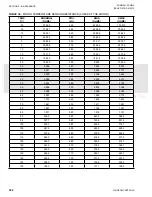

Chiller / Compressor Operating Log

A Chiller/Compressor Operating Log is supplied on

Page 329 for logging compressor and chiller operating

data.

EVACUATING A SYSTEM

If a system or a portion of a system needs to be evacu-

ated, it should be evacuated to a minimum of 500 mi-

crons. The system should then be able to hold the vacu-

um for 10 minutes with a maximum rise of 50 microns.

If the system is not able to hold a vacuum, recheck the

system for leaks.

Summary of Contents for YCIV0157

Page 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...