JOHNSON CONTROLS

46

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

SECTION 4 - INSTALLATION

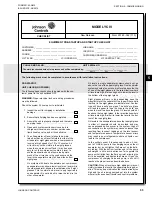

PIPEWORK ARRANGEMENT

The following is a suggested piping arrangement for

single unit installations. For multiple unit installations,

each unit should be piped as shown in

-Isolating Valve - Normally Open

-Isolating Valve - Normally Closed

-Flow Regulating Valve

-Flow Measurement Device

-Strainer

-Pressure Tapping

-Flow Switch

-Flanged Connection

-Pipework

FIGURE 5 -

PIPEWORK ARRANGEMENT

LD10507

CONNECTION TYPES AND SIZES

For connection sizes relevant to individual models re-

COOLER CONNECTIONS

Standard chilled liquid connections on all coolers are

of the Victaulic Groove type (See

FIGURE 6 -

VICTAULIC GROOVE

LD10494

Option Flanges

One of two types of flanges may be fitted depending

on the customer or local Pressure Vessel Code require-

ments. These are Victaulic-Adapter flanges, normally

supplied loose, or weld flanges, which may be sup-

plied loose or ready-fitted. Victaulic-Adapter and weld

flange dimensions are to ISO 7005 - NP10.

FIGURE 7 -

FLANGE ATTACHMENT

LD10495

WELD FLANGE

VICTAULIC

REFRIGERANT RELIEF VALVE PIPING

The evaporator is protected against internal refrigerant

overpressure by refrigerant relief valves. A pressure re-

lief valve is mounted on each of the main refrigerant

lines connecting the cooler to the compressors.

A piece of pipe is fitted to each valve and directed so

that when the valve is activated the release of high

pressure gas and liquid cannot be a danger or cause

injury. For indoor installations, pressure relief valves

should be piped to the exterior of the building.

The size of any piping attached to a relief valve must

be of sufficient diameter so as not to cause resistance to

the operation of the valve. Unless otherwise specified

by local regulations. Internal diameter depends on the

length of pipe required and is given by the following

formula:

D5 = 1.447 x L

Where:

D = minimum pipe internal diameter in cm

L = length of pipe in meters

If relief piping is common to more than one valve, its

cross-sectional area must be at least the total required

by each valve. Valve types should not be mixed on a

common pipe. Precautions should be taken to ensure

the outlets of relief valves or relief valve vent pipes

remain clear of obstructions at all times.

Summary of Contents for YCIV0157

Page 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...