Table 1: Operation analysis chart

Results

Possible cause

Remedy

Pre-rotation vanes

fail to open.

Check the

pre-rotation

vane motor

positioning

circuit.

High chilled water temperature.

System overload.

Be sure the

vanes are wide

open (without

overloading the

motor) until the

load decreases.

4. Symptom: No oil pressure when

SYSTEM START

button pressed

Oil pump running

in wrong direction.

Check rotation

of oil pump

(Electrical

Connections).

Low oil pressure displayed on control center; compressor

will not start.

Oil pump not

running.

Troubleshoot

electrical

problem with oil

pump VSD.

5. Symptom: Unusually high oil pressure develops when oil pump runs

Unusually high oil pressure is displayed when the oil

pressure display key is pressed when the oil pump is

running.

High oil pressure.

Transducer

defective.

Replace low or

high oil pressure

transducer.

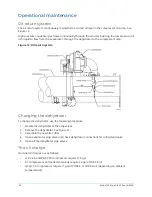

6. Symptom: Oil pump vibrates or is noisy

Oil not reaching

pump suction

inlet in sufficient

quantity.

Check oil level.

Oil pump vibrates or is extremely noisy with some oil

pressure when pressing

OIL PRESSURE

display key.

Note:

When oil pump is run without an oil supply it

will vibrate and become extremely noisy.

Worn or failed oil

pump.

Repair or replace

oil pump.

7. Symptom: Reduced oil pump capacity

Excessive end

clearance pump.

Other worn pump

parts.

Inspect and

replace worn

parts.

Oil pump pumping capacity.

Partially blocked

oil supply inlet.

Check oil inlet for

blockage.

8. Symptom: Oil pressure gradually decreases (Noted by Observation of Daily Log Sheets)

When oil pump VSD frequency increases to 55 + hz to

maintain target oil pressure.

Oil filter is dirty.

Change oil filter.

9. Symptom: Oil pressure system ceases to return an oil or refrigerant sample

29

Model YK Style G R-134a or R-513A