Manual description

Form number

Wiring Diagram – Field Connections for YK Chiller (Style G) OptiView™ Control

Center with Remote Medium Voltage VSD

160.75-PW3

Wiring Diagram – Field Control Modifications for YK Chiller (Style G)

160.75-PW4

Wiring Diagram – YK Chiller (Style G) OptiView™ Control Center with Remote Low

or Medium Voltage EMS

160.75-PW5

Wiring Diagram – YK Chiller (Style G) OptiView™ Control Center with Unit Mounted

Low or Medium Voltage SSS, Unit Mounted Low Voltage VSD with Modbus, or

Remote Medium Voltage VSD

160.75-PW6

Wiring Diagram – YK Chiller (Style G) OptiView™ Control Center with LTC I/O Board

with Remote Low or Medium Voltage EMS

160.75-PW7

Wiring Diagram – YK Chiller (Style G) OptiView™ Control Center with LTC I/O Board

with Unit Mounted Low or Medium Voltage SSS, Unit Mounted Low Voltage VSD

with Modbus or Remote Medium Voltage VSD

160.75-PW8

Renewal Parts – Unit

160.75-RP1

Renewal Parts – OptiView™ Control Center

160.54-RP1

Conditioned based maintenance

Traditional chiller maintenance is based upon assumed and generalized conditions. In lieu of

the traditional maintenance program, a Johnson Controls YORK conditioned based maintenance

(CBM) program can be substituted. This CBM service plan is built around the specific needs for

the chiller, operating conditions, and annualized impact realized by the chiller. Your local Johnson

Controls Branch can propose a customized Planned Service Agreement that leverages real time

and historical data, delivering performance reporting, corrective actions required and data enabled

guidance for optimal operation and lifecycle assurance. The program will include fault detection

diagnostics, operation code statistics, performance based algorithms and advance rules based

rationale delivered by the Johnson Controls Connected Equipment Portal.

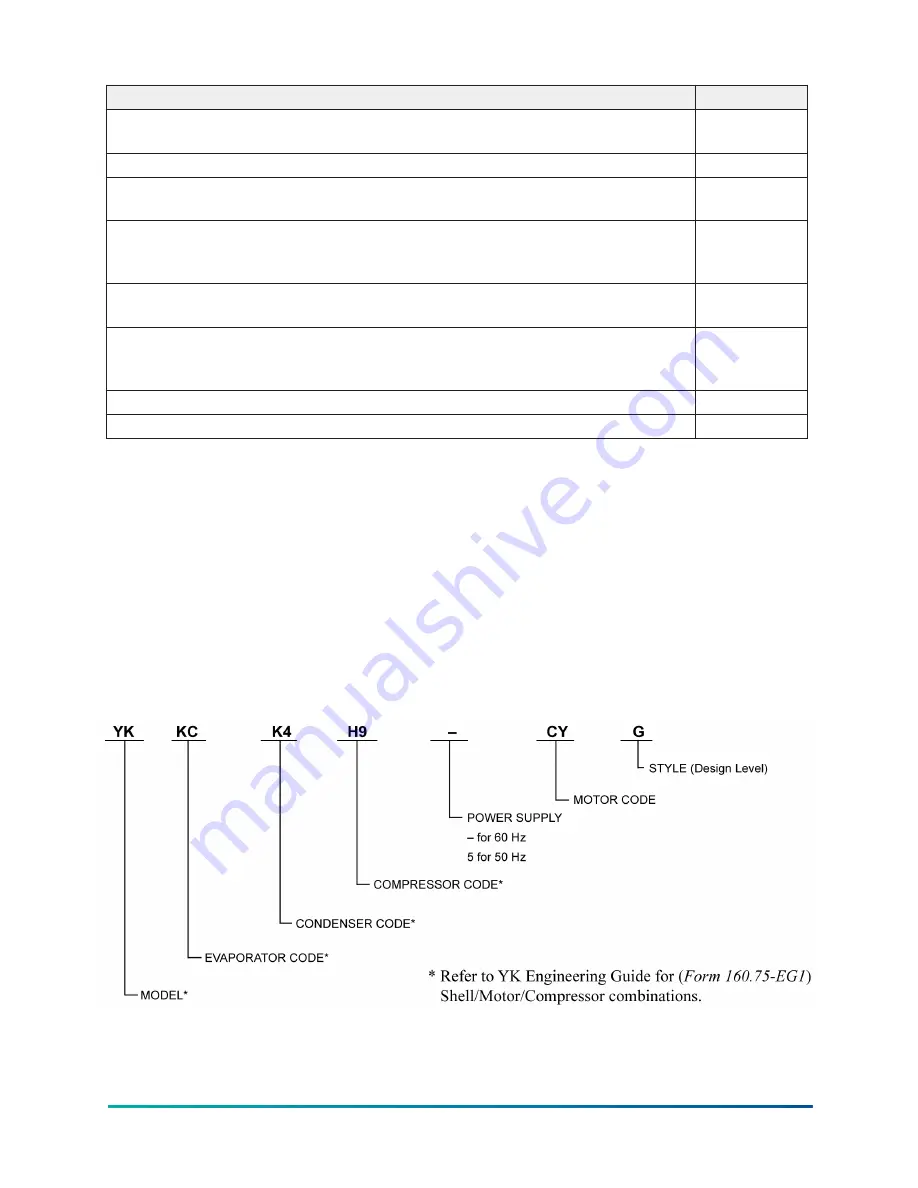

Nomenclature

7

Model YK Style G R-134a or R-513A