johNSoN coNtroLS

2-70

ForM 102.20-N1 (1109)

installation

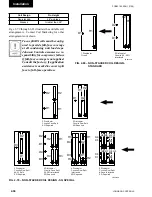

Installation of a 2” Prefilter In Combination with

a Single Header Final Filter

These instructions are for installing a 2” prefilter,

(typically PerfectPleat, Premium or Premium HM

pleated filter) used in combination with a single header

final filter (typically VariCel SH or DriPak 2000) into

16 ga. galvanized holding frames.

• Latches needed for this application are four (4)

P/N 026-35778-000 and four (4) 026-35778-007

as shown in Fig.2-98.

Follow instructions for Single

Headered (SH) filters then proceed

with this procedure for 2" Pre-filters.

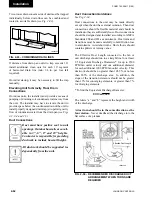

installation of latches

1. Insert the straight end of the latch (P/N 026-35778-

007) between the two (2) knockouts furthest from

the corner.

2. Using a moderate amount of pressure, force the

latch over the third knockout

(See Fig. 2-104).

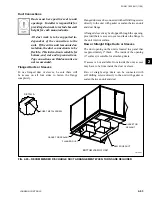

3. After both filters have been placed into the frame,

grasp the loose end of the latch and place it over

the prefilter frame, so that the latch secures the

prefilter to the SH filter. Repeat for the remaining

latches.

4. The filters should now be securely installed into

the frame,

as shown in Fig.2-105.

Fig. 2-104 – inStAll lAtCh P//n 026-35778-007

LD010496

Fig. 2-105 – inStAllEd CARtRigE W/PlEAtS

LD010160

Installation of SH Single Headered Filters

These instructions are for installing single header filter

(typically VariCel SH or DriPak 2000 filter) into 16 ga.

galvanized holding frames.

• Latches needed for these applications are four

(4) P/N 026-35778-000,

as shown in Fig.2-98.

• A single latch should be installed at each of the

four (4) corners of the frame.

• The latch fits into the set of knockouts, which

consists of two (2) rows of three (3) knockouts

.

The row of knockouts closest to the gasketing

should be used for nominal 1” filters or filters

with a 13/16” single header. The second set of

knockouts should be used for nominal 2” fil

-

ters.

installation of latches

1. Insert the straight end of the latch between the two

(2) knockouts furthest from the corner.

2. Using a moderate amount of pressure, force the

latch over the third knockout

.

3. The latch installation should now be complete. The

latch should now be “trapped” within the three (3)

knockouts, but should be able to freely rotate

.

Repeat the installation process with the remaining

latches.

4. Rotate all of the latches outward, and insert the SH

filter into the frame

.

The bulk of the filter should

be inserted through the frame, protruding out the

backside. Only the header of the filter should be

contacting the flange of the frame.

5. After the filter has been placed into the frame, grasp

the circular end of the latch and rotate it across the

corner of the filter

.

Push the end of the latch towards the filter, until the

latch catches beneath the knockout on the frame.

Repeat for the remaining latches.

6. The filter should now be securely installed into the

frame

(see Fig.2-103).

Fig. 2-103 – inStAllEd CARtRidgE FiltER

LD010148

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...