3-13

johNSoN coNtroLS

ForM 102.20-N1 (1109)

3

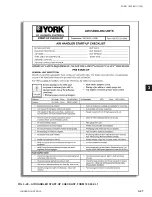

10. Visually check that the high temperature safety

limit is set for a 200-230°F range. The limit switch

is typically mounted behind the burner control

panel.

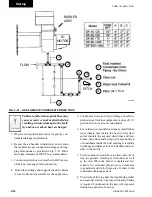

11. Connect a 0-15"

gas pressure gauge or other suit-

able instrument to the gas manifold port. The gas

pressure will be measured when running (

refer to

step 4 of Burner Start-up Procedure).

On Powerflame burners this test port

is downstream of the main regulator,

typically on a standard tee fitting in the

main gas line.

On Eclipse burners, this test port is

located on the backside of the burner,

just below the spark igniter. A small

valve is provided at this test port.

12. Connect a manometer or other suitable device to

the Heat Exchanger Draft Port located on the side

of the unit near the burner. The expected draft

should read slightly negative – about -.03

"

WC.

The draft port is typically made of ¾"

steel pipe

and may be plugged. Remove plug and add a small

stop valve and a nipple for a rubber tube

(see Fig.

3-15 and 3-17).

13. Install the Honeywell S7800 Test Module (display),

if available.

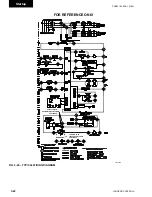

14. Connect signal generator (0-20mA) to terminals in

place of modulation control signal (for 2-10 VDC

signal add a 500 Ω resistor in series).

See Fig.

3-24.

15. Visually check that the flue (stack) is secure and

connected properly. Typical connections are shown

at the end of this guideline

(see Fig.’s 3-22 and

3-23).

16. Burner panel off/on switch should be “off”

System is now ready for start up.

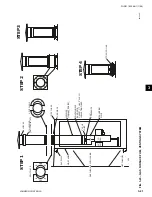

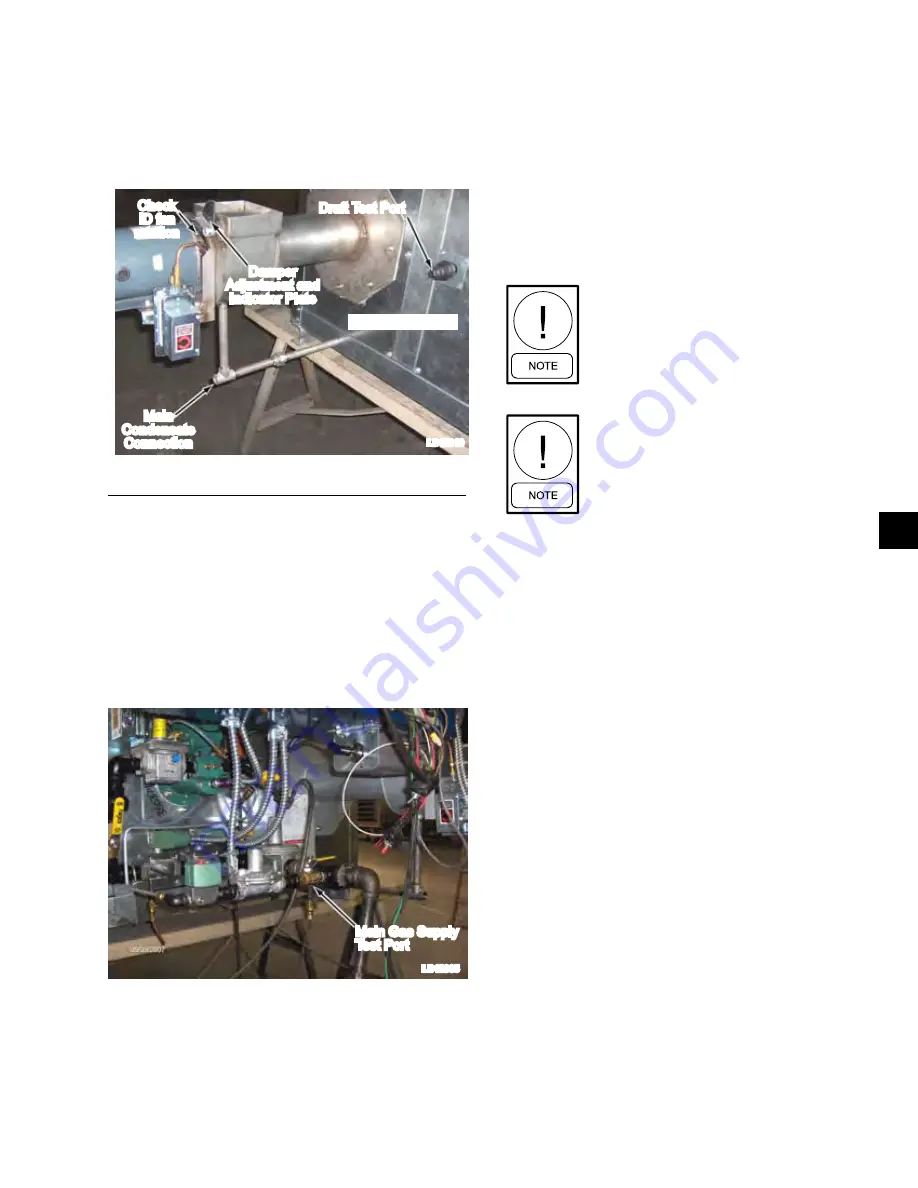

7. The flue (stack) damper is located at the discharge

of the ID blower and closed for shipping. Release

the locking mechanism and set the damper to match

the position indicated by the scribed markings.

Lock in place

(see Fig. 3-15).

Fig. 3-15 – SEt id FAn dAMPER

8. Inspect condensate drain trap to see that it is large

enough, as described in this guideline

(see Fig.

3-21).

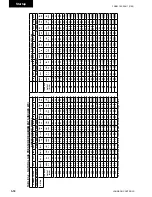

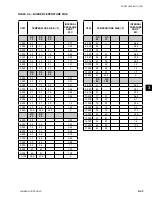

9. Measure the gas supply pressure coming into

the gas train

(see Fig. 3-16).

Gas pressure can be

greater than shown on the “Burner Test Report”,

but it must be between the min/max values listed

in Table 3-2.

Fig. 3-16 – ChECK MAin gAS SuPPlY

PRESSuRE

ld12910

Burner panel

Check

iD fan

rotation

draft test port

Damper

adjustment and

indicator plate

Main

condensate

connection

ld12905

main gas Supply

test port

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...