3-15

johNSoN coNtroLS

ForM 102.20-N1 (1109)

3

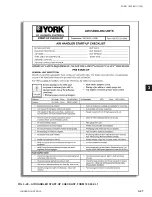

7. Using the signal generator, cycle the burner to

check capacity modulation. Observe valve/damper

actuator operation.

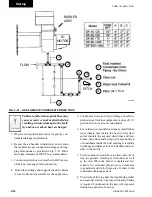

Fig. 3-19 – dAMPER ACtuAtOR

8. Using the standard operating controls, cycle the

burner several times to assure proper sequencing

of start-up, firing, and capacity modulation, plus

operation of all safety and monitoring controls.

9. Test 180°F. high temperature safety by running

burner with airflow off or diverted. Burner

will shut down at 180°F. Turn air handler on as

quickly as possible to remove heat from the heat

exchanger.

10. Burner efficiency testing should be done last. The

burner should be running at High Fire rate for 30

minutes before efficiency testing is done.

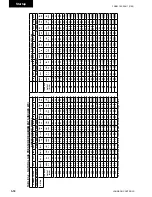

11. Efficiency at High Fire is pre-determined, but may

be checked by flue gas analysis at the entrance to

the ID Blower Housing Test Port. At High Fire

CO

2

should be between 8-1/2 and 10 %; 0

2

should

be between 7-1/2 and 4%. With these ranges, effi

-

ciency is 80% plus or minus 2%

(see Fig. 3-18).

12. Contact contractor, facilities manager or customer

to inform successful start-up has been complet-

ed.

In the unlikely event that adjustment

is required; it is done at High Fire and

must NOT retard low Fire light-off.

Do not change set up of factory preset

air inlet dampers on Power Flame

burner.

Any questions should be directed to

your local Service office or Johnson

Controls Product Tech Support, before

contacting the burner manufacturer.

Fig. 3-20 – COndEnSAtE dRAin

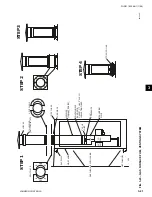

Condensate Drain Arrangement

The YORK Solution Indirect Fired gas heat exchanger

has the potential to create highly acidic condensation,

particularly during extended operation at low capacity

or low firing rate conditions. To insure proper drainage

the following guidelines should be followed

(See Fig.

3-21).

When constructing the condensate trap

for the heat exchanger drainage sys-

tem, make sure the trap is tall enough

to handle the Total Static Pressure of

the ID Blower at low Fire times 2.

Example: TSP is 6” at low Fire -

construct trap 12” tall (See Table in

Fig. 3-21).

LD12911

ld12909

Damper

actuator

marked by factory,

future reference for

actuator set up.

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...