johNSoN coNtroLS

2-40

ForM 102.20-N1 (1109)

installation

Available Control Options

• Staging - No controller, but contactors are

energized by providing control power to each

contactor from external BMS source.

• Step Controller - device to receive a 0- to 10 VDC

or 4 to 20 mA signal and step on heat stages.

• Vernier SCR - completely electronically con

-

trolled by varying signal and varying output

between stages. Increases power to a stage by

modulation until another stage is needed. Ener-

gizes another stage and modulates power until

another stage is needed. 0 to 10 VDC or 4 TO

20 mA. Less expensive than Full SCR. This

system utilizes a step controller and one SCR

that modulates and resets for each stage.

• Full SCR - completely electronically controlled

by varying signal and varying output of a control-

ler. Like a VFD for electric heat. 0 to 10 VDC or

4 to 20 mA. The controller modulates a separate

SCR for each stage.

Installation

Rotating parts and electrical shock

hazards exist. Lock out and tag out

the fan motor(s) and heat power

disconnects before servicing. FOl-

lOW THE lATEST “lOCKOUT

TAGOUT” PROCEDURE. Failure to

follow proper safety precautions may

result in serious injury or death

APPliCAtiOn inFORMAtiOn

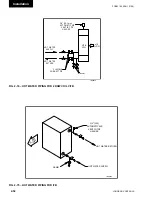

1. Follow the procedure given in this instruction to

find the minimum air velocity for safe operation

(see Fig. 3-25).

At least this minimum velocity

must be provided at all points over the heater face

area. Failure to meet this requirement may result

in serious damage or nuisance thermal cutout trip-

ping.

2. The maximum air inlet temperature for open coil

heaters is 100°F, and for finned tubular heaters,

80°F.

3. Sufficient working space must be provided per

paragraph 110-26 of the NEC.

4. This electric heater is not designed for or intended

to be used for temporary heat prior to system

startup / balancing.

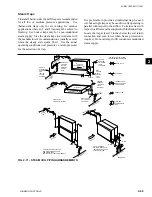

MEChAniCAl inStAllAtiOn

1. All heaters will contain an adjustable airflow

switch in the heater control panel. This switch

will be preset to close at a differential pressure of

approximately 0.3" W.C.

In all cases the switch will be connected to a pres-

sure probe positioned in the airstream. This probe

has an arrow stamped on it that is viewable from

inside of the control panel. When the heater is

located upstream of the fan this arrow will point

away from the fan. When the heater is located on

the downstream side of the fan the arrow will again

point away from the fan or with airflow.

If it is incorrectly installed, remove the (2) screws

holding the pressure probe in place and rotate 180°

and reinstall. The airflow switch pressure port that

is not connected to this pressure probe will be run

to the exterior of the air handling unit to source a

reference differential pressure. In some situations

it may be necessary to adjust this airflow switch

setting to allow for proper operation. Precautions

must be made at this time to make sure that the

airflow switch does not provide a false indication

of airflow. Failure to meet this requirement may

result in serious damage or nuisance thermal cutout

tripping

(see Fig. 2-60 and 2-61).

2. A visual inspection of the heater elements should

be made prior to use of the heater. If physical

damage is evident, a Megohm test should be used

to validate the heater elements are safe for use. If

a minimum value of 10 megohms is not achieved

then any damaged elements or ceramic insulators

must be replaced prior to operation.

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...