2-55

johNSoN coNtroLS

ForM 102.20-N1 (1109)

2

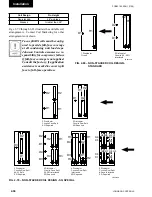

DX Coil Types

There are three basic types of coil arrangements used

in field erected split systems, interlaced, row split and

face split.

interlaced

Interlaced coils are the most desirable type of coil “field

erected” designs. Interlaced coils ensure the entire face

of the coil is active with any number of compressors

operating. Interlaced circuitry interweaves coil tubing

in both circuits across the entire face of the coil assuring

uniform cooling of the air by the refrigerant. This type

of coil also allows one circuit to operate while the other

circuit is turned off. Interlaced coils provide excellent

temperature control at full and part loads as well as

good TXV superheat control. TXV control is essential

for compressor reliability.

Row Split

Row split coils arrangements place coils back to back

in the air stream. Air passes through one coil before

passing through the next. Generally, the last coil in

the air stream is activated first. Each circuit may be

controlled independently in this arrangement. When

both coils are operating, the coil closest to the leaving

air will operate at a lower temperature. This type of

coil may not permit lead lag of the circuits and it may

be difficult to balance the capacity between the coils

Face Split

On a face split coil, the circuiting is divided between

two separate coils. In field-erected systems, this

arrangement may suffer from TXV superheat control

problems and compressor reliability. At low airflow,

low load situations, the TXV may have difficulty

controlling system superheat.

Air stratification, poor humidity control and

condensation on downstream components can also

occur when using face split coils. One way to address

TXV control at part load is to provide a face damper to

shutoff airflow when a coil face is inactive.

Combined Coil types

Coil types may be combined in some systems. This

requires special care. Control sequences and piping

tying the multiple systems and coils together should

be well thought out and advice from an experienced

design engineer is necessary.

DX Coil Circuiting

On many coil banks, two, or even all three of the

methods of circuiting may be combined depending

upon the cooling capacity and the level of control

required. However, coil sections must be married or

combined so that they provide for full-face operation

(

see Fig. 2-78

).

There are numerous coil arrangements available from

the Coil Marketing group as either standard designs

or contract engineering SQ optional designs. The coil

designs fall into the two following categories.

FIG. 2-78 – DX COIL CIRCUITING TYPES

LD13319B

FACE SPLIT

ROW SPLIT

INTERLACED

LEGEND

WARM AIR

COLD AIR

REFRIGERANT IN

REFRIGERANT OUT

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...