2-61

johNSoN coNtroLS

ForM 102.20-N1 (1109)

2

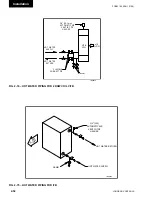

Condensate Drain Trap

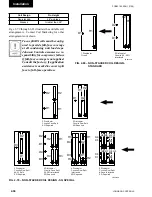

For “Draw Through” applications install a trapped

condensate drain line at unit drain connection (

see Fig.

2-91

) according to all governing codes. “H” dimension

must be at least 1 inch greater than design Total Static

Pressure (TSP) of fan. This ensures proper drainage

even if filters clog or dampers malfunction.

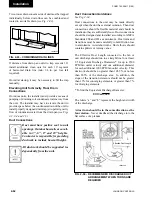

For “Blow Through” applications, the same principles

apply, but the leaving pipe must be as shown in Fig.

2-92 for proper trap design.

"H" must be at least

1 inch plus fan total

static pressure

"X" = 1/2 "H"

H

Fig. 2-91 – tRAP dEtAil FOR dRAW thROugh

APPliCAtiOn

LD05370-2

Fig. 2-92 – tRAP dEtAil FOR BlOW thROugh

APPliCAtiOn

LD05371-2

"H" must be at least

1 inch plus fan total

static pressure

H

Drain

Connection

Top of trap must be equal to or

lower than bottom of unit drain

connection.

drains And traps

Heat trace and insulate traps where

there is a risk of freezing to prevent

blockage and/or damage due to freez

-

ing of the liquid in the trap.

Auxiliary drain pans may not require

traps. If the trap is not in constant use

the water seal may evaporate causing

air passage into or out of the air han-

dler. In such cases it is recommended

to cap the drain in a manner that al-

lows opening or closing of the drain

depending on its use.

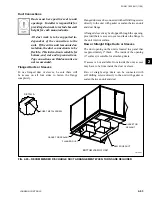

Condensate Drain Piping

The majority of cooling coils are located in the units so

that the supply air is drawn through them. This results

in the condensate being subjected to negative (-) static

pressure. Unless some means of pressure equalization

is provided in the condensate drain, the air rushing

back through the drainpipe will cause the condensate

to build up in the drain pan. As the unit continues to

operate, the accumulated water will be carried with the

air stream, overfilling the drain pan causing possible

water leaks into the supply duct and/or causing water

damage in the building. A trap must be installed to

prevent this condensate water build-up (

see Figs 2-90

and 2-91

).

Fig. 2-90 – dRAin tRAP ShOWing WAtER

lOCAtiOn duRing dRAW thROugh

OPERAtiOn StAgES

LD06342-1

DRAIN

PAN

DRAIN

PAN

DRAIN

PAN

DRAIN

NIPPLE

TRAP

NO.1 - FAN OFF

NO. 2 - TRAP CONDITION WHEN FAN STARTS

NO. 3 - FAN RUNNING AND CONDENSATE

COOLING COIL

DRAIN PAN

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...