150

JOHNSON CONTROLS

FORM 201.21-NM4 (616)

150

JOHNSON CONTROLS

TECHNICAL DATA

EQUIPMENT START-UP CHECK SHEET (CON'T)

UNIT WARNING: INVALID SERIAL NUMBER

ENTER UNIT SERIAL NUMBER

operation. Whenever the pump contacts are used, the

coil of the pump starter should be suppressed with an

RC suppressor (031-00808-000).

PANEL CHECKS

(POWER ON – BOTH SYSTEM SWITCHES “OFF”)

You are about to turn power on to this

machine. Safety is Number One! Only

qualified individuals are permitted to

service this product. The qualified

individual furthermore is to be knowl-

edgeable of, and adhere to, all safe

work practices as required by NEC,

OSHA, and NFPA 70E. Proper per-

sonal protection is to be utilized where

and when required.

1. Assure the chiller OFF/ON UNIT switch at the bot-

tom of the keypad is OFF.

2. Apply 3-phase power to the chiller. Turn ON

the optional panel circuit breaker if supplied. The

customer’s disconnection devices can now be set to

ON.

3. Verify the control panel display is illuminated.

4. To prevent the compressors from starting, assure

that the system switches under the SYSTEM

SWITCHES key are in the OFF position.

5. Verify that the voltage supply corresponds to the

unit requirement and is within the limits given in

the Technical Data Section.

6. Ensure the heaters on each compressor are on using

a clamp-on ammeter. Heater current draw is approx.

3A.

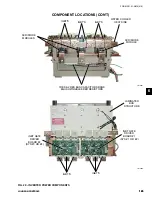

7 . Verify the “Factory Set” Overload Potentiometers

on the VSD Logic Board are set correctly (correct

settings are found on Page 298). Press the VSD

DATA key and using the arrow keys, scroll to the

compressor overload settings. Verify the “Factory

Set” overload potentiometer(s) on the VSD logic

board (see FIG. 16) are set correctly. In the un-

likely event that they are not set correctly, adjust

the potentiometers until the desired values are

achieved.

The VSD is powered up and live. High

voltage exists in the area of the cir-

cuit board on the bus bars, VSD Pole

Assemblies, and wiring to the input

inductor.

Adjust the potentiometers, if needed, using the table on

page 297. The locations of the potentiometers are shown

in FIG. 20, page 134. The potentiometers are Sys 1=R19,

Sys 2=R64, Sys 3=R42, and Sys 4=R86.

Incorrect settings of the potentiometers

may cause damage to the equipment.

Record the Overload Potentiometer settings below:

Compressor Overload Setting:

System 1 = ______________ Amps

System 2 = ______________ Amps

System 3 = ______________ Amps

System 4 = ______________ Amps

8. Press the STATUS Key. If the following message

appears, immediately contact YORK Product

Technical Support. The appearance of this message

may mean the chiller has lost important factory

programmed information. The serial num-

ber and other important data may need to be

reprogrammed.

Changing the programming of this

feature requires the date and time to

be set on the chiller prior to program-

ming. Additional information regard-

ing this message and how to enter the

serial number with the factory provided

password is outlined in the SERIAL

NUMBER PROGRAMMING informa-

tion on Page 263