294

JOHNSON CONTROLS

FORM 201.21-NM4 (616)

294

JOHNSON CONTROLS

MAINTENANCE

EVACUATING A SYSTEM

If a system or a portion of a system needs to be evacuat-

ed, it should be evacuated to a minimum of 500 microns.

The system should then be able to hold the vacuum for

10 minutes with a maximum rise of 50 microns. If the

system is not able to hold a vacuum, recheck the system

for leaks.

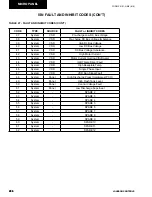

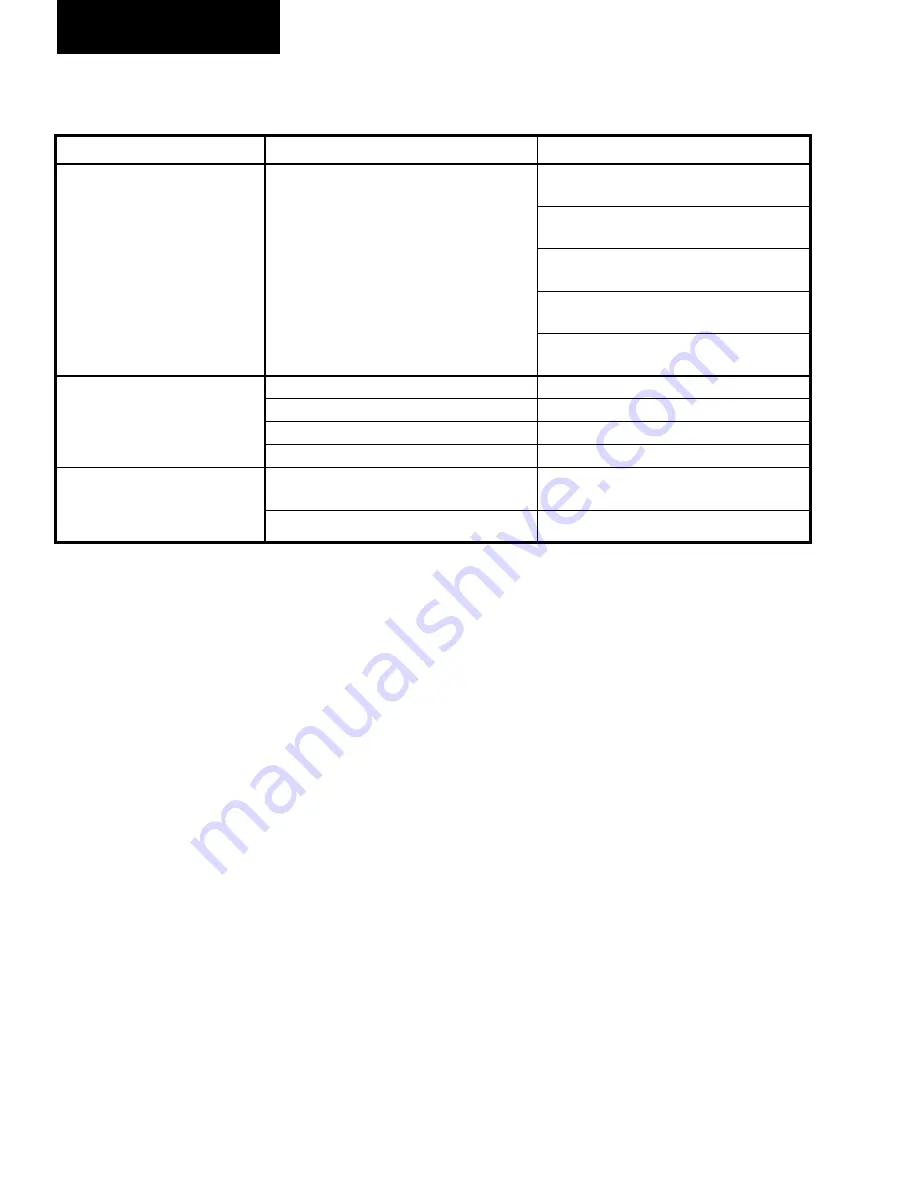

TROUBLESHOOTING GUIDE (CON'T)

PROBLEM

POSSIBLE CAUSE

ACTION

System Fault:

MOTOR

CURRENT

LIMITING

High motor current

has activated

current limiting

Ambient temperature is high,

normal response from controller

Remote or panel limiting is in

effect, Normal response.

Excess charge in system,

adjust charge.

Condensor coils dirty,

Clean condensor.

Fans NOT operating,

Check fans.

VSD Fault:

High

Baseplate

Temperature

Coolant level low.

Add coolant.

Glycol Pump is defective.

Replace Glycol Pump.

VSD Board is defective

Replace VSD Logic Board.

IGBT Module is defective.

Check defective IGBT Module.

VSD Fault:

Low DC

Bus Voltage

SCR / Diode Module

is defective.

Check SCR / Diode Module.

SCR Trigger Board is defective.

Check SCR Trigger board.

(Always remove power to the chiller and assure the DC bus voltage has bled off)