Document Number: SE00458000-00

Page 16

3.5.

MOTOR INSTALLATION – LINEAR

STAGES

After the Carriage is mounted on the Base the motor can be mounted. SE motors can be mounted

on either of the

motor’s two flat surfaces.

To install SE motors using the M5 motor thread option, use the following items:

Allen wrench

– M5 for SE8 motor.

Screw and washer

– M5 for SE8 motors.

Screw length should be sufficient to pass the base and contact at least 1/ 2 the depth of the motor

body. If the screw protrudes from the motor, care should be taken that it does not interfere with the

movement of other stage parts such as the stroke of the upper axis.

3.5.1.

MOUNTING SE4 AND SE8 MOTORS ON LINEAR

STAGE

Nanomotion SE4 and SE8 motors have a preload screw. The motor is supplied with the preload

screw in the locked position and ready for mounting on the stage.

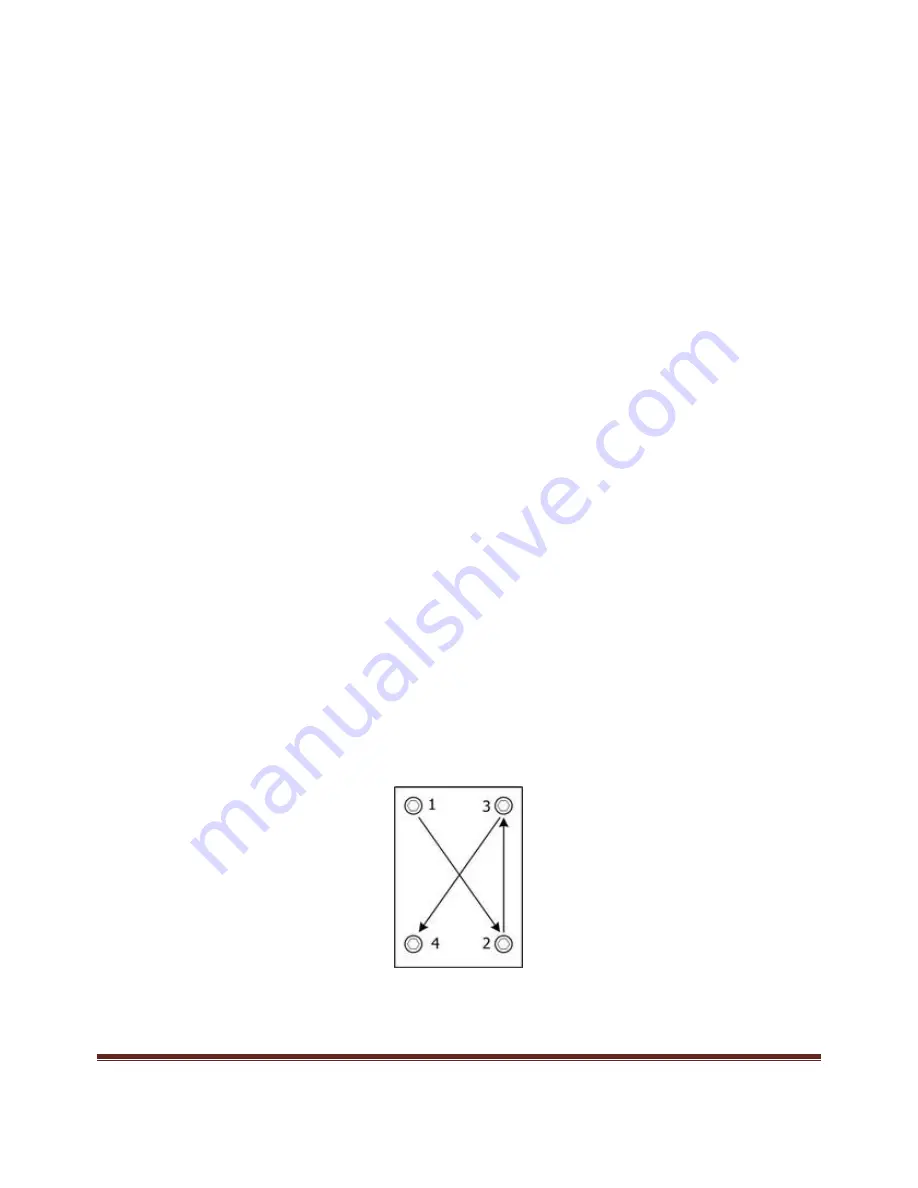

1. Ensure that the preload ex-center is positioned such that the dot on its upper

surface is farthest from the reference point on the motor case (Figure 9(A)).

2. Set the motor in place and finger-tighten the four mounting screws (M5) and

washers. Apply a small amount of blue Loctite to the screws before

mounting.

The motor should be secure but able to move.

3. Press the motor so that the motor tips are against the Drive Strip.

4. Using a diagonal sequence, tighten the four mounting screws (M5).

To ensure that the motor does not move during this process tighten the

screws 30% of the required torque first, then tighten them to full torque.

5. Apply a torque of 0.5 to 0.7 Nm to each screw.

6. Turn the Preload screw CW or CCW until the dot on the screw is closest to

the reference point on the motor top cover (Figure 9(B)).