85-03-00954

18 |

P a g e

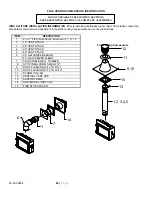

FRAMING DEPTH and FINISHING GUIDES

The nominal framing depth for this fireplace is 14-5/8 inches. This is a fixed depth required for all installations, except a

corner installation and for installations that use solid Granite or Marble slabs or thick natural stone materials as fascia ma-

terials. For corner installations, see General Appliance Specifications and Planning the Installation Sections.

For installing solid Granite or Marble slabs as fascia material, reduce the framing depth by ½” then install ½” thick drywall

on the framing studs so that the drywall is flush with the front face of this fireplace. Install the Granite or Marble slab so

that it adheres to the face of the fireplace and the drywall.

Finishing Guide

Only one set of Finishing Guides are supplied with this fireplace. Guides protrude out 1” from the face of this fireplace.

Guides are factory secured using rivets and may be removed by drilling through the rivets using 1/8” drill bits if not needed

or may be permanently left in place.

NOTE:

All Decorative options available for this appliance shall employ the “factory-mounted guides” for locating the inner

edges of the Finishing material adjacent to the convection air gaps. All decorative options available for this fireplace either

fit inside the “factory mounted guides” or fit on top of the surface of the final finishing material selected.

MAXIMUM THICKNESS OF FINISHING MATERIAL ALLOWED:

A maximum 3” thickness of material is allowed to be placed on top of the flat face of this fireplace and still allow all deco-

rative Fronts options to mount and function properly. If the total thickness of finishing materials on top of the flat face of

this appliance is to exceed 3”, reduce the framing depth accordingly or contact Mendota Technical Service for support.

RECOMMENDED BACKING MATERIALS OVER NON-COMBUSTIBLE ZONES

:

See R-Ratings tables provided in the next page.

Mendota recommends the use of ½” thick Mineral Fiber Boards or Ceramic Boards in the non-combustible zones as

backer material when you want a smooth painted finish around this fireplace. Select a backer materials which has an R-

value greater than R 1.0. Follow backer material manufacturer's instructions to apply drywall compound or cement com-

pounds to achieve the smooth finish.

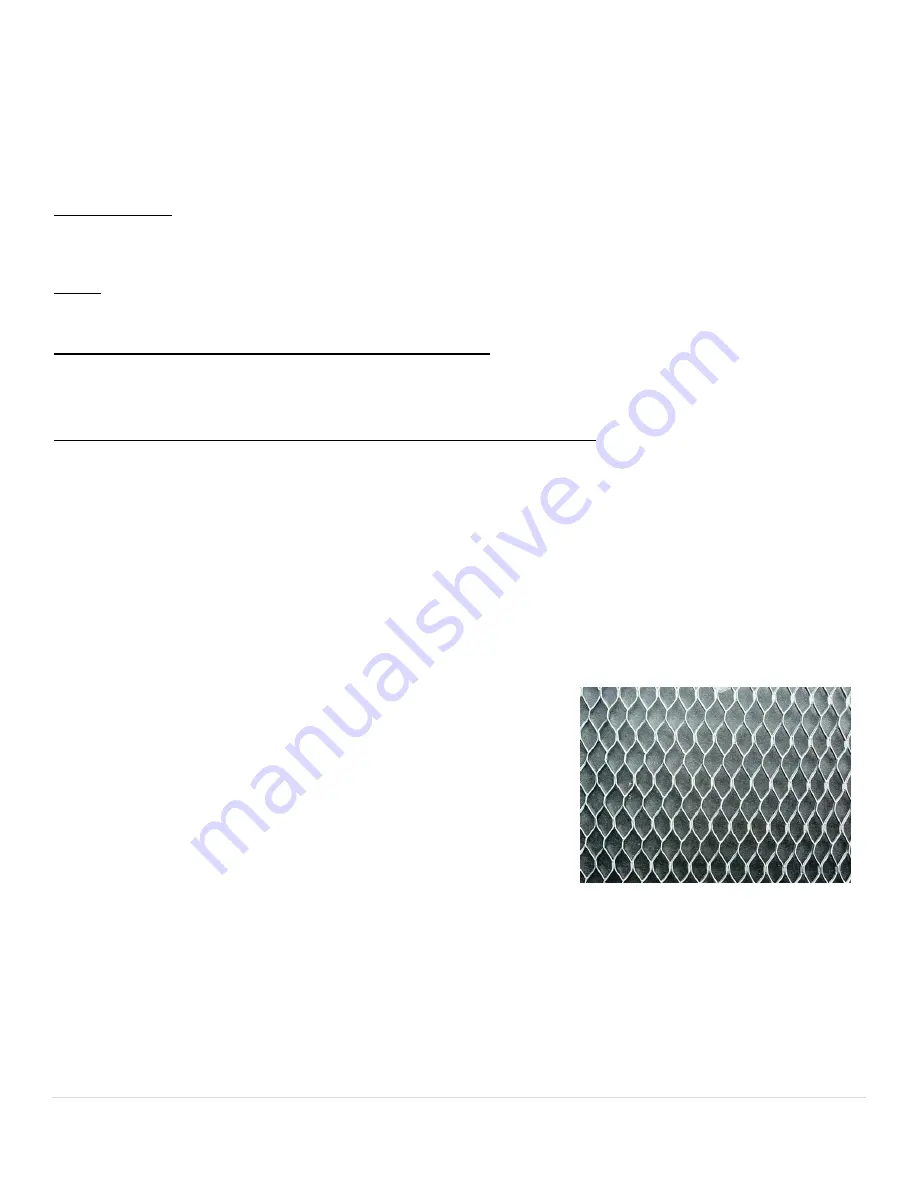

For applications where you want a smooth painted plaster finish over the Mineral/Ceramic Board, cut to size and secure

metal lath screen to the top surface of the Backer board using 1” long screws which penetrate the screen, Backer board

and the combustible rough framing for this appliance and under the Backer Board.

For applications where you want to attach tiles or stone slabs to the Mineral/Ceramic Board, cut to size and secure metal

lath screen to the top surface of the Backer board using 1” long screws which penetrate the screen, Backer board and the

combustible floor structure under the Backer Board.

Proceed by applying ThinSet mortar (with no polymeric additives) which will

not off gas at high temperatures and place tiles or stone slab on the ThinSet

surface.

For Hearthpad applications where you want employ Marble, Granite, Stone

slabs or ceramic tiles, select a base backer board which has an R-Rating

greater than 1.0. Attach Marble, Granite, Stone Slabs or ceramic tiles on top

of the backer board you selected.