85-03-00954

32 |

P a g e

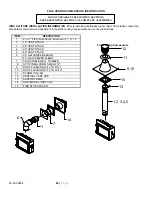

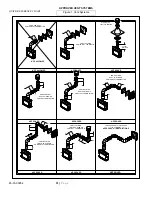

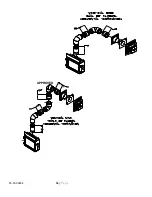

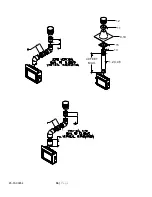

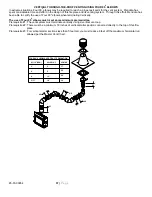

ONE(1) 90° ELBOW

TOP VENT

HORIZONTAL TERMINATION

H

V

MINIMUM RISE (18”) WITH HORIZONTAL TERMINATION

The FV-34 Fireplace must be installed by a qualified Mendota approved serviceperson.

A Maximum Horizontal Run allowed is 6 inches if an 18” vertical starter section and one 90-degree elbow is connected

directly to this fireplace’s flue starter collar.

When a 90-degree elbow is connected directly to this fireplace, the horizontal centerline of the 90

º

elbow will be 49-1/2”

inches up from the floor level of this Fireplace.

See, MASTER FLUE VENTING REQUIREMENTS CHART and Figures, below.

Use "fixed" pipe sections in place of adjustable pipe section

s wherever possible. 1000

º

sealant must be used on ALL

inner pipe joints that do not have factory installed gasket material.

Always maintain 1" clearance from vent pipe sides and bottom to combustibles, 2" clearance on top of pipe on horizontal

runs and on top of horizontal discharge elbows. Do not fill air spaces with insulation or other material.

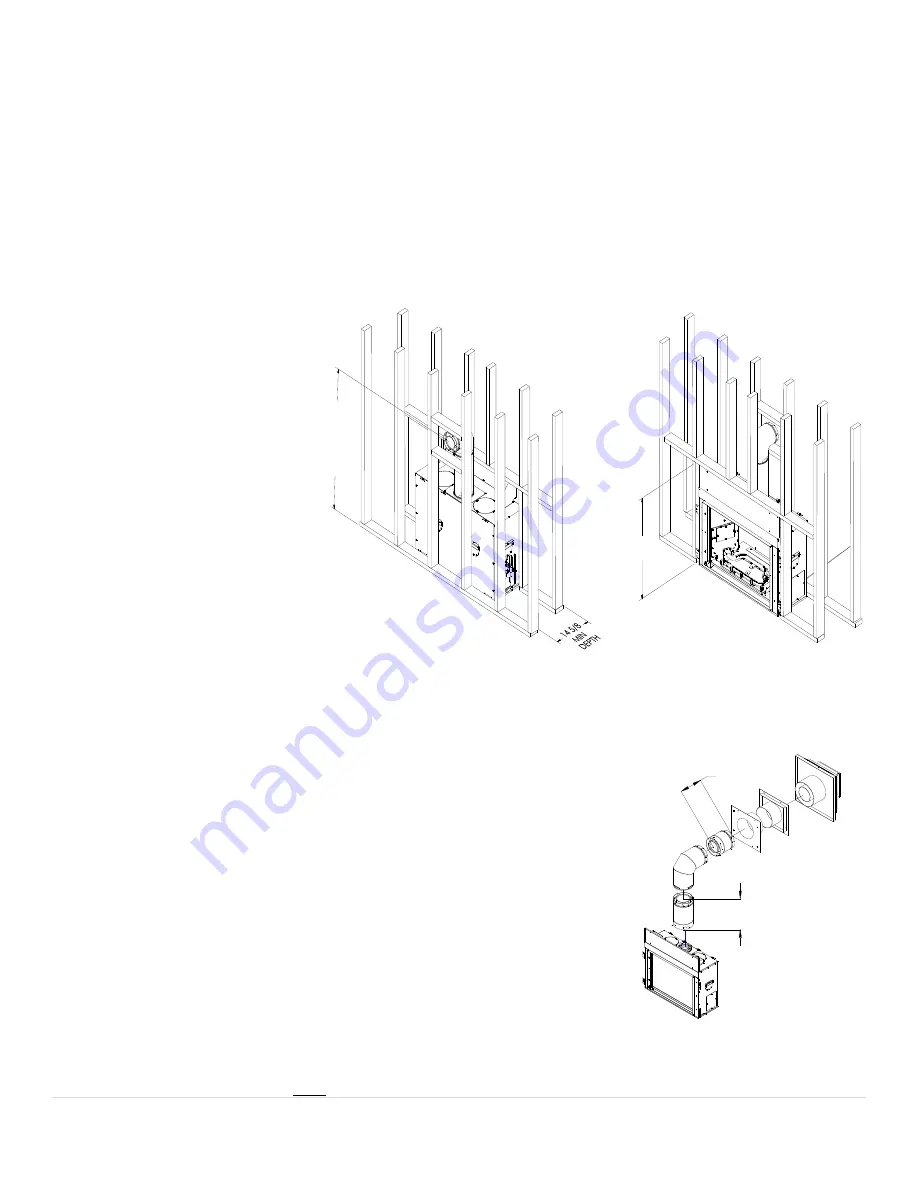

1. Position fireplace in desired loca-

tion. See guidelines on proper

vent cap placement on the exte-

rior of home. Check to deter-

mine if wall studs are in the way

when venting system is attached.

If this is the case, you may want

to adjust the fireplace location or

modify the exterior wall framing

to allow the vent system to pene-

trate the wall.

2. Measure from the floor level of

the fireplace up 49-1/2” inches

and mark wall directly at the cen-

ter of where the vent pipe will

penetrate the exterior wall.

3. Cut and frame a 9" wide x 10"

high opening in the wall. The

hole must be positioned so the

vent system will have a ¼" rise

per foot of run AND be perpendicular to the wall. The height of the opening must be located to meet all local and na-

tional building codes. Do not allow the termination to be easily blocked or

obstructed. If wall being penetrated is non-combustible material, i.e. ma-

sonry block, brick, etc., an 8-inch diameter hole is acceptable.

4. Attach the 18” straight section to the fireplace starter adapter. Attach a

90-degree elbow to the top of the 18” vertical starter section and rotate

and lock in position. Attach a horizontal section to the 90-degree elbow.

Be sure all vent component connections are in their fully twist-locked posi-

tion and are leak-proof. Be sure 1000

º

sealant is used on the inner pipe

joints of all pipe sections manufactured by Simpson DuraVent. The length

of the horizontal piece that fits through the wall will be determined by the

location of the fireplace relative to the wall. For a normal installation

where this fireplace is installed directly against an exterior wall construct-

ed using 2x4 lumber or 2x6 lumber, only a 6” horizontal section is re-

quired. There MUST be a minimum of 1" air space clearance to

combustibles from all vent components (2" above horizontal runs and hor-

izontal discharge elbows).

5.

A wall thimble must always be used when penetrating combustible

wall materials.

6. From the exterior of the home, slide the horizontal vent cap over the end

of the horizontal pipe and tightly secure the cap to the wall with screws.

Seal with a high quality caulking.

NOTE:

Combustible wall thickness must be 4" to 8" maximum. Vent Cap shall not be recessed into wall or siding.

49-1/2"

FLOOR

TO

WALL

THIMBLE

CENTER

37"

FINALIZED

HEIGHT