JOINT MAKING OPERATIONS

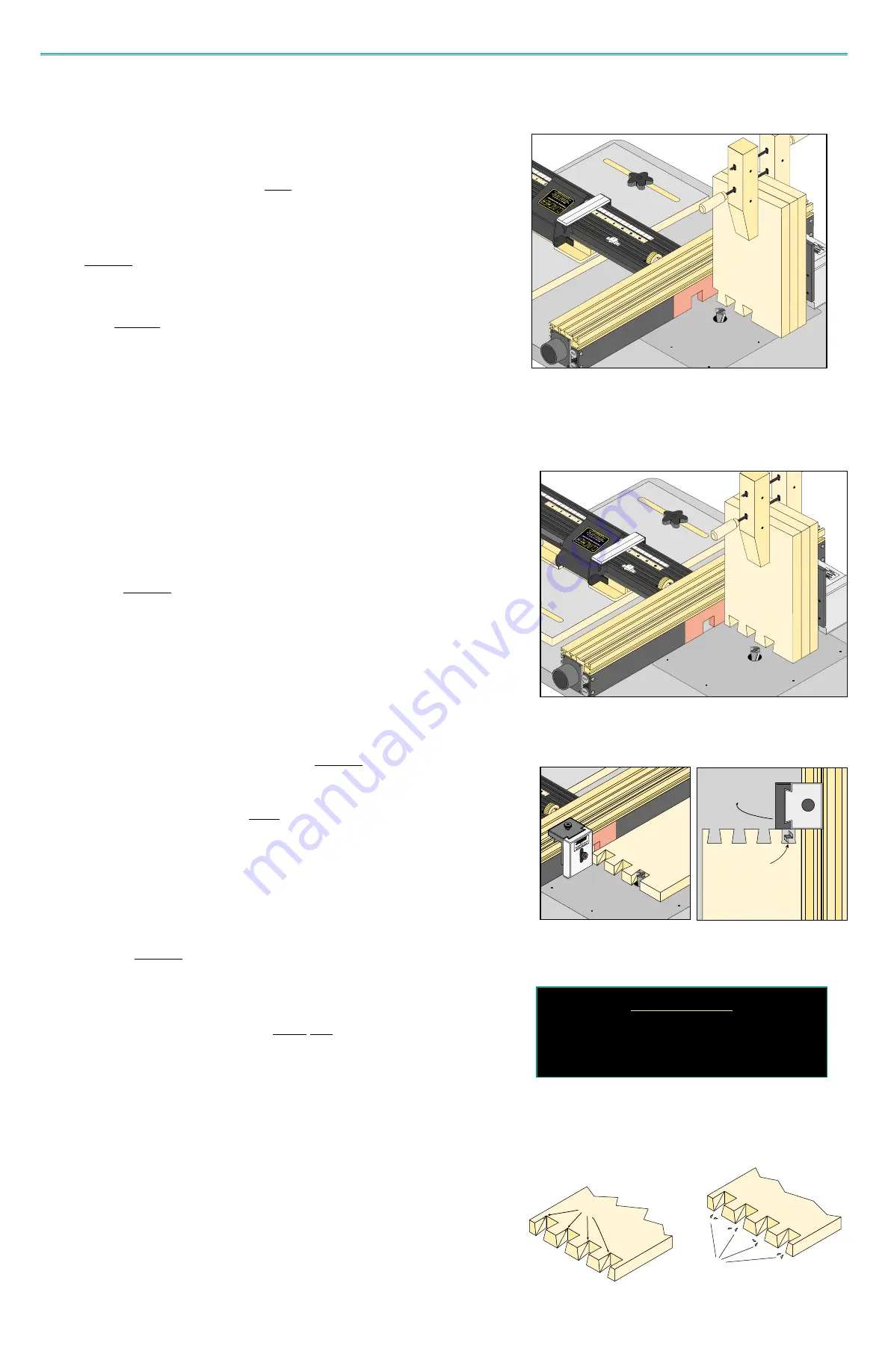

7. Making the Pins

Pins are normally made by passing the workpiece horizontally into the bit. The Jointech

Through Dovetail employs both a horizontal (sliding) cut and a vertical cut to make the

pin. Both operations are made with the same bit at the same height setting. Use the

assigned template lines for pins to make both cuts to the pin boards.

a.

THE VERTICAL CUT

Just as in making the tails use the VPF, Stop Block and a backup board to

prevent splintering. Be sure the end of the workpieces are down on the table

top and the

reference edge is against fence. Several pin boards may be

stacked together for cutting in one pass.

b.

THE HORIZONTAL CUT

This step requires a sliding cut to be made into each dovetail pin cut made in

the previous step. It is important to use the Stop Block to limit the length of

this cut. The preciseness of this cut is especially important since you will be

removing a very small sliver of material to create the straight cut required of a

through dovetail. The steps that follow will insure that you will have a perfect

fit, perfect appearance and an even fit at the ends of the joint.

NOTE: This operation will also require that the reference edge of each

board be placed against the fence for making cuts on both ends.

This means that cuts on one end of the board will be made from

the infeed side of the fence. This cut will have to be made with the

Stop Block placed on the infeed side of the cutter.

(1) Set CLINCHER to a pin cut on the template.

(2) Orient the dovetail bit as shown so that its cutting edges are parallel to

the fence.

(3) Place the pin workpiece flat on the table and slide forward until it just

contacts the bit cutting edge at the inside back edge of the dovetail cut.

Move the workpiece back approximately 1/64” and lock the Stop Block

in position.

(4) Place the

reference edge of the pin workpiece against the fence. Use a

rubber-soled push block and perform the series of sliding cuts to this one

end of board only.

(5) Repeat all the above steps for the other end of each pin piece except all

the cuts will be made from the outfeed toward the infeed side of the cutter

with the Stop Block located on the infeed side.

Even though you are

removing only a small sliver of material in this cut, it is in the “WRONG”

direction for the rotation of the bit. Exercise great care to hold the workpiece

firmly against the fence to prevent the bit from grabbing and throwing the

workpiece away from the fence.

6. Making the Tails

The tails are made with all the cuts through the end grain with the boards vertical and at

right angles to the table and the fence. Use the following procedure and the assigned

template lines to make the tail boards.

NOTE: Some through dovetail template patterns require the CLINCHER to be

micro-adjusted to a

1

/

64”

setting prior to making the tail cuts. If called for on

the full-size plan page, this will be a one-time adjustment made before

starting the series of cuts. The adjustment is made by turning the

thumbwheel to the

1

/

64”

setting.

(1) Clamp your tail boards to the Vertical Push Fixture with a backing board and

reference edge against fence as shown. Be sure the work is down against the

table top and against the fence to keep it square. Set your Stop Block to stop

the VPF before it can be damaged by the bit.

(2) Perform the series of tail cuts. Flip the boards end for end and repeat the same

cuts. NOTE: The first cut on the tail board will be an open cut meaning that

you will be cutting away the edge of the board adjacent to the fence. To prevent

this first cut from splintering, make the cut in several side by side passes.

(3) After completing all the tail cuts rotate the thumbwheel back to the Zero position.

8. The Final Fit

On the face side of the pin workpiece you will notice a very small nub remaining. This is

due to the radial cut of the bit and will be more or less pronounced depending on how

closely your board thickness matches the depth of cut.

With soft woods this nub will cold-form to a straight line and be virtually unnoticed.

However, this is not the case with a hard species of wood. If the appearance of the pin

face is important to you remove the tiny nub with a sharp knife.

C

CA

AU

UT

TI

IO

ON

N

Do not lift the workpiece to clear the

chips or for any other reason with

the wood over the cutter.

Position Stop Block

so that router bit

does not cut into

this flat surface.

Stop Block

Remove small nub left

from router bit.

Waste

17