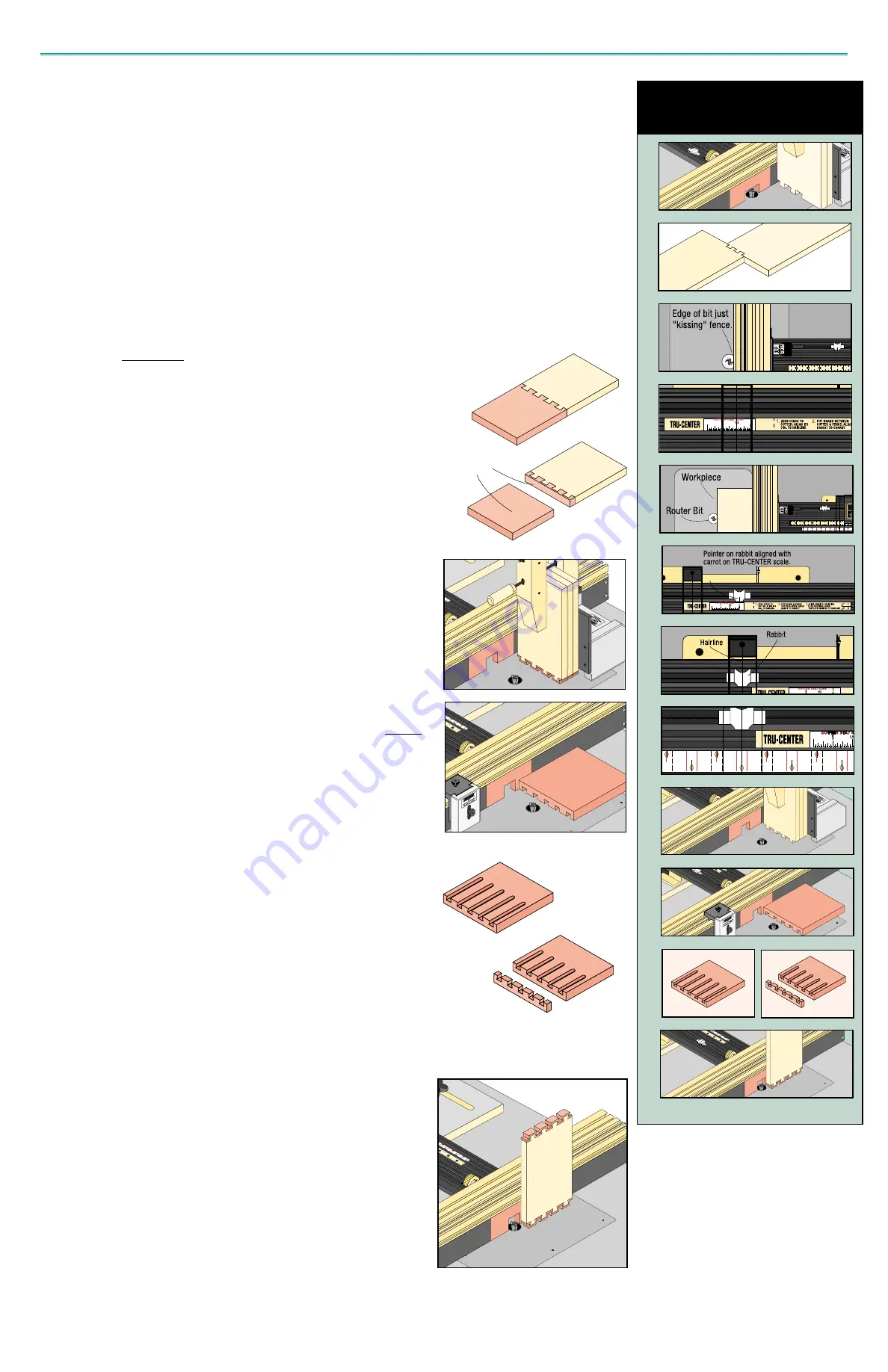

JOINT MAKING OPERATIONS

7. Making The Pins

Perform the pin cuts from the assigned template cut lines determined in Step 1 above.

a.

HALF-BLIND DOUBLE-DOVETAILS

Complete the pin workpiece in the same manner as for a conventional Half-Blind

dovetail. Refer to the previous section,

Half-Blind Dovetails, Step No. 5.

b.

THROUGH DOUBLE-DOVETAILS

Complete the pin workpiece in the same manner as for a conventional Through

Dovetail pin piece. Refer to the previous section,

Through Dovetails, Step No. 7.

8. The Middle Section

Methods for making the middle section for both Half-Blind and Through

Double-Dovetails are the same.

Note: Wall thickness dimensions given on

plan pages are approximate. To insure that the top and bottom wall sections

end up precisely the same thickness as the side wall sections, it is suggest-

ed that you first make test cuts using scrap pieces.

a.

VERTICAL METHOD

(1) Select a workpiece for the middle section. It should be of the same

width and thickness as the tail workpiece and long enough to clamp

to the Vertical Push Fixture.

(2) Clamp the middle piece vertically to the VPF and perform the

assigned series of cuts which will mate the center section to the tail

workpiece.

(3) Fit the dovetailed ends of the middle piece and the tail board

together and glue and clamp in place. Allow to dry.

(4) Place a mark on the middle section workpiece which will extend the

length of the tail boards by the

wall thickness amount found on the

respective full size plan page. On a table saw, cut off the middle

section to the mark.

(5) Clamp this longer tail board to the VPF and perform the series of

cuts which will mate to the pin workpiece. The tail board can now be

trial fitted to the completed pin board.

b.

SLIDING METHOD

(1) Select a suitable workpiece for the middle section. The board should

be several inches long and same width as your tail and pin work

pieces, but of thicker stock. Plane it to a dimension that is greater

than the depth of your dovetail cut by the

wall thickness amount

found on the respective full size plan page. As in the previous

method, test cuts will determine the precise thickness required to

achieve uniform wall thickness.

(2) Make only the one series of cuts which will mate with the tail work

piece. Be sure to use a rubber-soled push block for all sliding cuts.

(3) Using a support board (ideally, a mating piece cut by following the

short template lines which would mate with the pin board), on a

table saw slice sections about

1

/

32”

wider that the tail board

thickness.

(4) Glue the sliced center section to the finished tail board. Allow to dry

and belt sand smooth.

(5) Clamp this longer tail board to the VPF and perform the series of

cuts which will mate to the pin workpiece. The tail board can now be

trial fitted to a completed pin workpiece.

9. The Final Fit

a.

HALF-BLIND DOUBLE DOVETAILS

Make a rabbet cut on the back side of each tail board. Refer to the

previous section,

Half-Blind Dovetails, Step No. 7.

b.

THROUGH DOUBLE-DOVETAILS

If your tail boards are thicker than the pins, a rabbet cut must be

made by following the same procedure as for a half-blind dovetail.

However, you should use a straight bit and set to the same height

as the thickness of your pin boards.

QUICK REVIEW

Double Dovetails

19

Tail Board

Middle Section

Workpiece

Tail Board

Middle Section

Workpiece

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

L.