With Jointech leading the way, the method of router table woodworking and

joinery has become the most exciting and sought after means to perform

shaping and cutting operations with high precision. The Jointech Ultra-

Precision Woodworking System which you have purchased will be the best

investment that you have made over any other tool in your shop. Far superi-

or to any other in quality, workmanship and versatility, the accuracy that this

new tool brings to your woodworking shop is unprecedented.

The CabinetMaker’s System is capable of jointing, routing, rabbeting, dado-

ing, making raised panels, and rail and stile frames. It can function as a saw

table fence, drill press positioner and much more. This one System will give

you the versatility needed to perform fine joinery and all cabinet-making

operations.

The Jointech Template Collection includes sixty, 16” long templates and

scales, plus step-by-step instructions to guide you through the use of the

templates to make box joints, half-blind dovetails, through dovetails, double

dovetails, double-double box joints, and the exotic Jointech Boxtail

TM

. Even

the novice, who perhaps has never made a simple dovetail or box joint, will

quickly be able to produce beautiful and intricate joinery in their projects.

Made entirely in San Antonio, Texas, Jointech’s American-made

Woodworking Systems have been met with enthusiastic approval of many

thousands of woodworkers, hobbyist and professional, as well as leading

experts in the field.

We thank you for choosing Jointech.

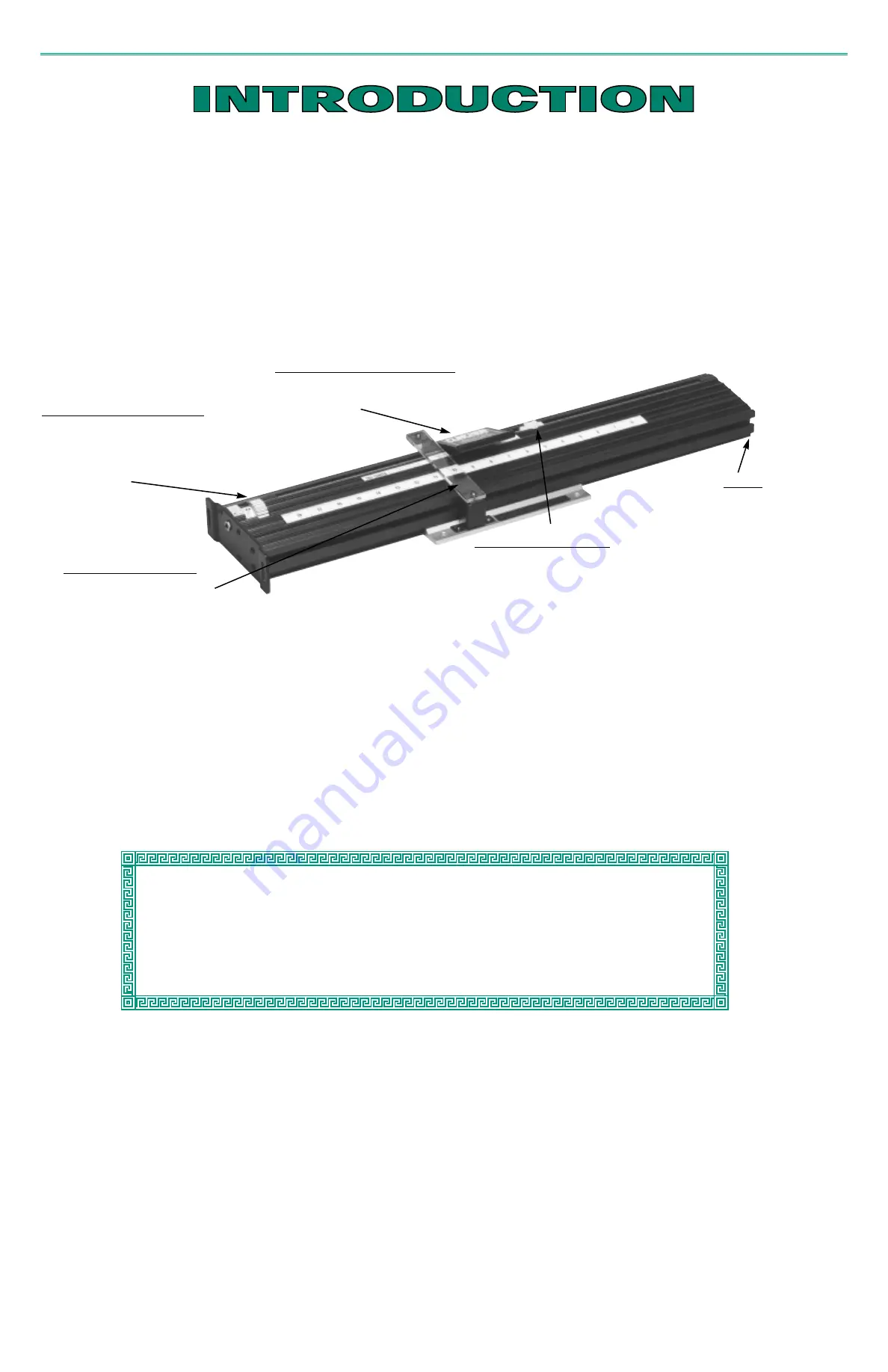

CLI NCH E R

Fence Machine

CLI NCH E R

Templates and Scales

JOINTECH warrants this product for five years from date of purchase against any defects that are due

to faulty material or workmanship. Please return the complete unit, transportation prepaid (proof of pur-

chase may be required) for free replacement or repair at our option. This warranty does not apply to

accessories. This warranty gives you specific legal rights and you may have other rights which vary

from state to state. Should you have any questions, contact Jointech, Incorporated.

HOME USE WARRANTY

(A FULL FIVE YEAR WARRANTY)

MICRO-ADJUST THUMBWHEEL

Each detent represents .001” of fence movement.

Decal indicates which direction fence will move

during rotation. After an adjustment, it’s scale sleeve

can be re-calibrated to Zero. Use thumbwheel only

when the cam-handle clamp is in the micro-adjust

position.

CAM-HANDLE CLAMP POSITIONS:

1) UPRIGHT - Carriage is released from leadscrew for full movement over its range.

2) 45 DEGREES - Position to make micro-adjustments with thumbwheel.

3) DOWN - Carriage is fully locked in place for a cutting operation.

ANTI-PARALLAX CURSOR

Visually align both top and bottom

hairlines to scale or template to

eliminate parallax.

CENTER FINDER

(RABBIT)

The

Rabbit and TRU-Center Scale are used to find the

exact center of a board. Follow directions on page 11

to achieve joint symmetry using any of the Jointech

templates. Once the TRU-Center Scale is calibrated to

a given cutter or blade kerf, only the Rabbit is used to

find center regardless of board width.

T-SLOT

A 5/8” wide flat nut

or a 1/2” - 14 deg.

dovetailed block

combined with a

handle or thumb-

screw can be

inserted into this

slot to make a

convenient carriage

handle and/or stop.

2

The

CLINCHER Template Collection includes 48 joint-making templates,

9 dual scales for making repetitive cuts, infeed and outfeed fence scales and

a blank inch scale for custom use. They are made from a special, high-

strength vinyl and will give many years of satisfactory use. The two printed

sheets comprising the 60 templates and scales are partially die cut and need

to be separated for insertion into the pockets provided for in this handbook.

Although they should separate easily by peeling apart, because of tolerances

in materials and manufacturing processes it may also be necessary to use a

sharp knife or razor blade.

The fit of a template or scale in a

CLINCHER slot may become too loose

over time. If this occurs, make a mild kink in one or more places along its

length to add tension when replaced in slot. You cannot damage a template

or scale in doing this.

If your templates become dirty, simply wipe them with a damp cloth. DO

NOT attempt to clean the templates with alcohol or any other solvent as this

may damage the printing.