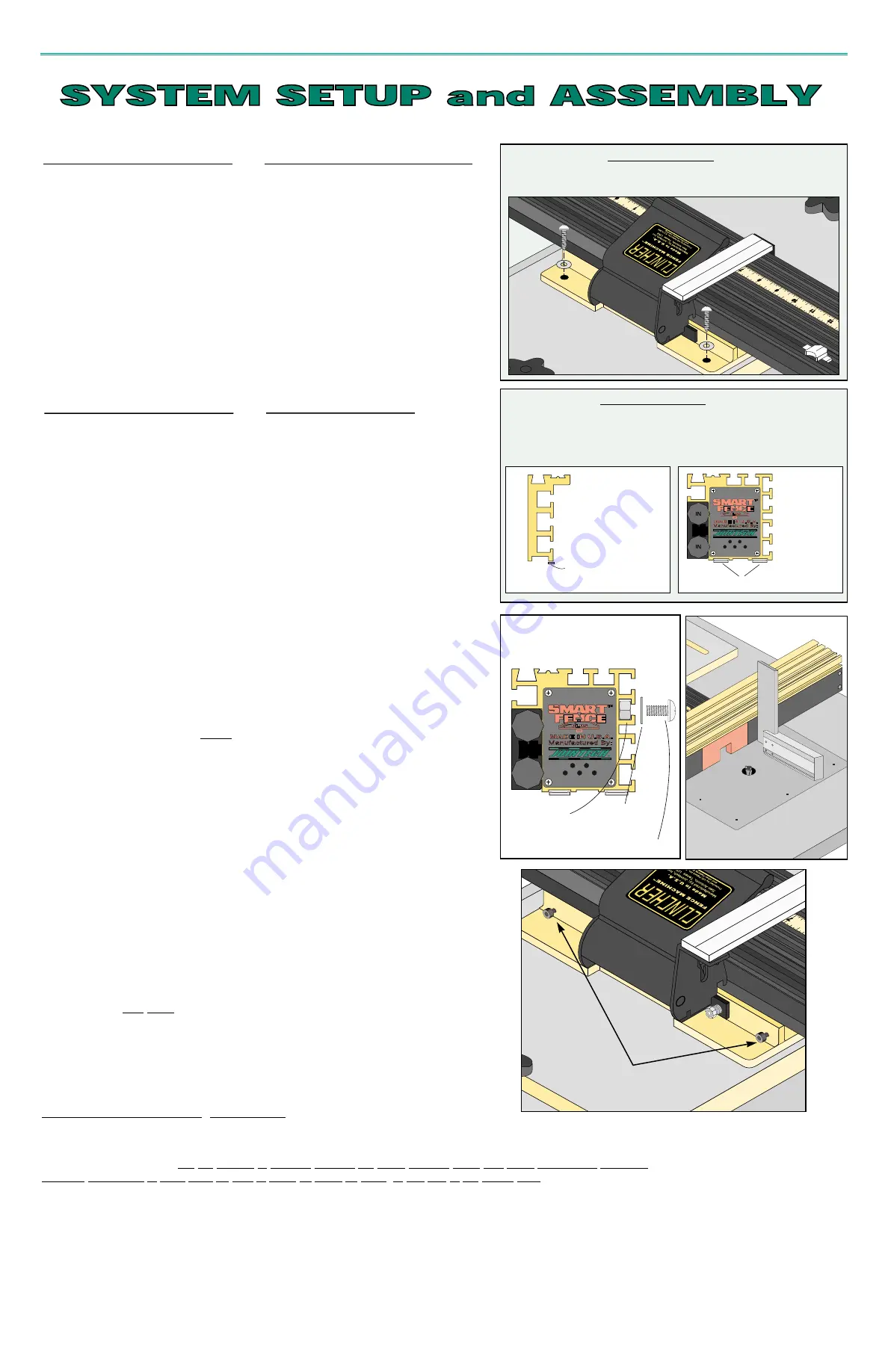

Fasten the

CLINCHER machine directly to your worktop surface or to a

movable base using the wood screws and washers provided. A movable base

should be

1

/

2”

to

3

/

4”

thick (

1

/

2”

maximum when using Joinery Fence), 8 - 10

inches wide and about as long as your top is wide if you plan to use C-clamps.

A slotted baseboard with carriage bolts and clamping knobs is easier to use

and provides a more finished appearance to your setup. Regardless of method,

the

CLINCHER must be mounted to an absolutely flat surface for optimum

performance and to prevent binding of carriage during movement. Additionally,

the fence mounting end of machine must remain parallel to table surface over

its entire range to prevent binding of fence against table surface. Check each

corner before tightening screws and add shims as necessary to achieve this

important first step. Check carriage movement and parallelism after tightening

screws.

Mounting Clincher

Fasteners Supplied

4 ea. - #10 x

3

/

4”

wood screws

4 ea. - #10 flat washer

1. Adhere an adhesive-backed nylon glide piece to bottom surface of fence at

each end. Position them so that they contact the table surface near its outer

edges;

For Joinery Fence, cut the glide pieces into narrow

strips and place only on rear edges of fence.

For SmartFence, cut into four short pieces and place

into the front and back shallow slots on bottom of fence.

2. Attach fence to the

CLINCHER fence mounting plate using the two 1/4-20

machine screws, flat washers and heavy hex nuts provided. Insert the two

nuts into the appropriate T-slot and slide toward center. (On SmartFence,

you may need to temporarily remove the two small fence-section clamping

knobs from one side.)

3. With the

CLINCHER fence machine securely mounted in place, align the

exact center of fence to the center of your router, insert screws with washers

through fence mounting plate to engage nuts and tighten. Check for

squareness of fence face to your table top. (With the SmartFence, you want

the square to touch the center of the black split sections since they protrude

out from the main fence by .005” - .010”.) It may be necessary to use shims

between machine and fence to achieve this one-time setup. You can use

adhesive-backed tape as shim stock adhering it to the fence mounting plate.

Move the

CLINCHER to the center of its range before final tightening of

screws.

4. Move

CLINCHER back and forth over its entire range to check for a smooth

travel without lifting or binding. Any dragging or binding over all or part of

the range may be a indication that the machine was not mounted level and

true or that there is a slight unevenness or twist in the table’s surface. This

condition can be corrected by one of two ways;

a) At the center of the

CLINCHER’S range, loosen fence fastening

hardware and temporarily place a thin shim under each fence

end under glide strip (or under the side that binds) to slightly

raise fence.

Re-tighten screws, remove shim and check movement again.

Repeat with a thicker shim and/or at different fence positions if

necessary.

b) Reduce gib tension on

CLINCHER. The two outer #10-32

socket cap screws on the base at back of machine determine

the freedom of

CLINCHER movement in the unclamped state.

Tightening of these two screws will restrict movement while a

very slight loosening of each will allow a more free movement

and alleviate binding of the fence. (Loosening of these gib

adjustment screws will not affect the performance during

micro-adjust or clamping force in the fully locked position of

cam handle. However, cutting SmartFence profile inserts

becomes more of a challenge when the fence has excessive

side-to-side play in its micro-adjust or unlocked position).

Fasteners Supplied

1 ea.

Nylon glide strip, 2

1

/

2”

long

2 ea.

1/4-20 x

1

/

2”

machine screw

2 ea.

1

/

4”

flat washer

2 ea.

1/4-20 nut, heavy hex

IN

IN

Mounting Fence

4

IMPORTANT NOTE:

It is VERY IMPORTANT that you follow the above steps to minimize friction in your final fence setup. When you place the

Cam-handle in its micro-adjust or fully locked position, you are engaging the 1/32” threads of a brass quarter-nut to the

stainless steel lead screw. For the threads to properly engage, the entire carriage setup with fence accessories (including

attached workpieces to VPF) must be able to move as much as 1/64”, or half that of the thread pitch. This engagement will

take place if you have followed the procedure above. However, if there is excessive friction in your system due to binding of

the fence or carriage, then it is possible that the threads may not fully engage and mesh together.

Therefore, take all the initial steps necessary to establish your fence machine setup to have the least amount of friction

possible. To insure that you achieve proper thread engagement it is also suggested that you visually check each setting by

carefully observing that the cursor hairlines are coincident to every template cut line or scale marks in the micro-adjust

position and after locking the cam handle. If you do not get proper engagement in the micro-adjust position, simply nudge the

carriage left or right with your hand.

Nylon Glide

Nylon Glides

1/4-20 nut

1/4-20 screw

flat washer

Gib Adjustment Screws

Joinery Fence

SmartFence