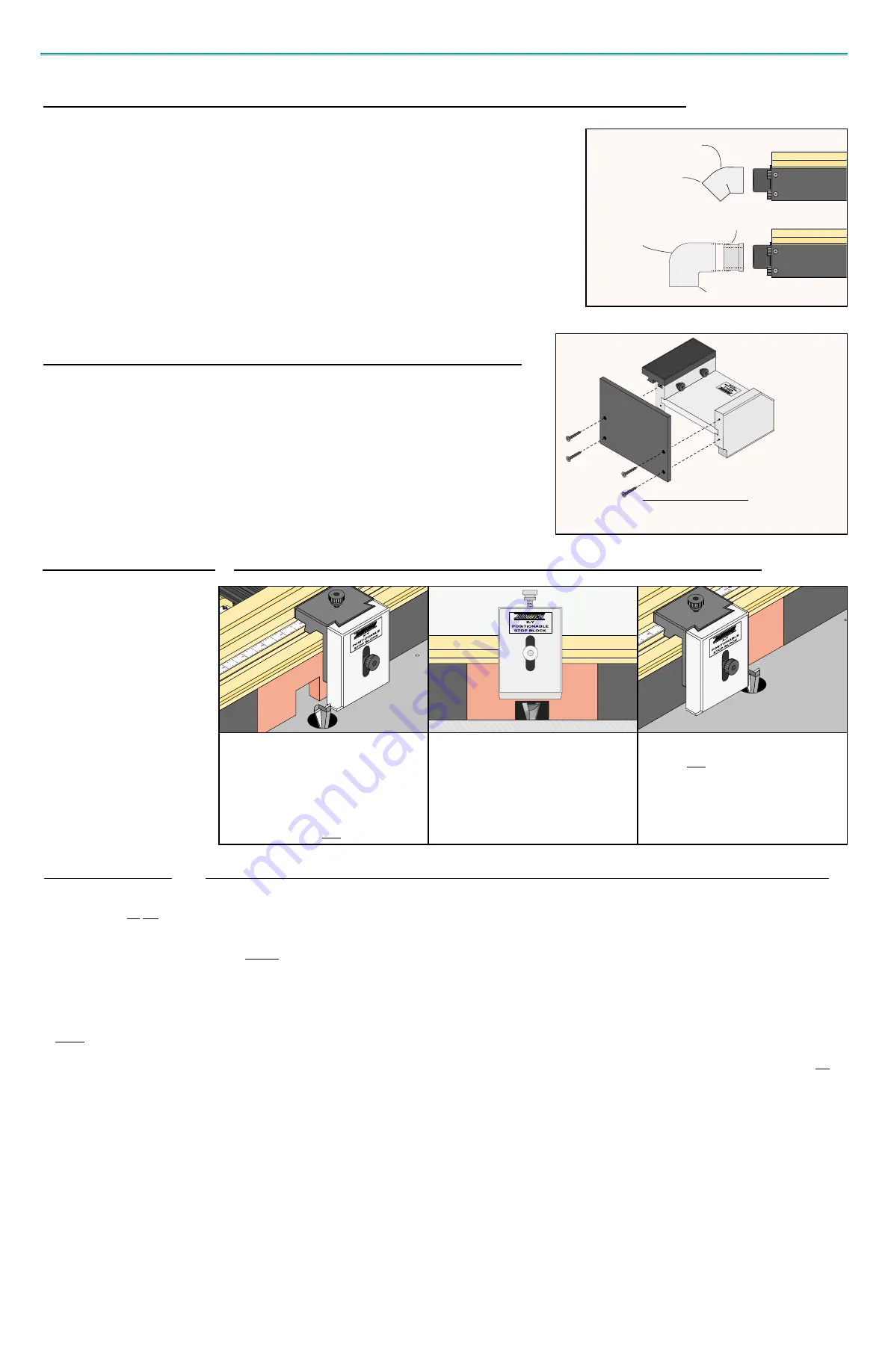

SYSTEM SETUP and ASSEMBLY

The vacuum port on the SmartFence is the size of a standard 1

1

/

4”

P.V.C. pipe. When a 1

1

/

4”

fitting

such as an elbow is attached, the O.D. is 2 inches which will accommodate most 2”, 2

1

/

4”

and 2

1

/

2”

hoses with hose clamps. If a larger O.D. is desired or required simply use PVC bushings and

fittings to increase the final O.D. size. For a more perfect fit to a non-standard hose duct tape may

be used to build up its outside diameter. P.V.C. fittings are available in most hardware stores and

home improvement centers.

Notes:

1.

A standard shop vac should have sufficient vacuum for all SmartFence operations.

2.

Vacuum MUST be used continuously when doing edge work to prevent chip buildup

within fence.

3.

Tapered design of vacuum port on fence will provide a snug fit with only light

pressure applied when connecting hose fitting.

Dust Collection Attachment

The black anodized aluminum face plate is attached to the VPF frame with the four drywall

screws. Start all four screws through the plate and into the pilot holes in frame assembly.

Tighten evenly until snug.

Insert the two 1/4-20 nylon thumbscrews into the threaded holes located at the top inside

frame adjacent to the dovetail runner. Install the VPF onto the fence. Adjust thumbscrews

until both just touch fence surface to remove side-to-side play of fixture. Over tensioning will

cause binding and may lift fixture entirely off table.

Check for squareness of fixture from table surface and from face of fence. If necessary, use

adhesive-backed tape as shim stock between frame and face plate to achieve squareness of

fixture.

Vertical Push Fixture

Fasteners Supplied

4 ea. - #6 x 1

1

/

4”

drywall screw

2 ea. - 1/4-20 x 1” nylon thumbscrew

The X - Y stop block is

adjustable both vertically and

horizontally. Two scales are

provided for accurate setting of

the stop to limit the length of a

cut at a precise distance from

either edge or center of a cutter.

They can be found in the

template set immediately after

No. 57. The scales are installed

in the top of the fence next to

the dovetail slot. Cut off any

excess after their installation

into fence.

The steps shown here

calibrate the outfeed scale to

the front cutting edge of bit.

1.

Orient bit cutting edges to run parallel with

fence.

2.

Insert stop block on infeed side of fence.

Lower the sliding vertical section and slide

stop forward on fence until its front edge

just contacts the outer cutting edge of bit.

Temporarily tighten top thumbscrew..

3.

Slide outfeed scale under stop block and

align its Zero to the front edge of stop block.

4.

Loosen top thumbscrew. Raise vertical

section and slide stop block forward on

fence until centered over bit. Lower the

vertical section to allow a small clearance

between bottom edge and top of bit.

Securely lock in place with side

thumbscrew.

5.

Now set the desired length of cut by sliding

the stop block forward and reading the scale

at the back edge of stop.

Cutting SmartFence Profile Inserts

GENERAL INFORMATION

1. Profile inserts do not have to be used. Also,

they do not offer any benefit in joinery. However,

they do add safety and improve cutting

performance for most cutters. Inserts cannot be

used for jointing or shaping operations whenever

fences are offset.

2. Always align centerlines of insert and fence to

center of router.

3. Never turn on router when cutter is within

profile of insert without first manually turning

cutter to insure clearance.

4. To remove insert, loosen infeed sliding section

and pull apart. If necessary, use a slot blade

screwdriver to pry apart. Be careful not to

damage or nick sliding section.

5. Once fence is centered to cutter, if you do not

loosen both sections simultaneously, inserts

will always remain centered to router.

6. Certain intricate cutter profiles may cause slight

chipping of insert when initially being cut. This

can be prevented by clamping a scrap board on

fence to bridge insert and cutting through both.

7. With blank insert installed and centered in

SmartFence, your

CLINCHER machine is moved

forward and into running cutter until profile has

been completely cut through. Profile inserts can

also be cut on a scroll saw or band saw.

SETUP FOR CUTTING

1. Move entire

CLINCHER setup as close to cutter

as possible. Align centerlines of insert and fence

to center of cutter and clamp in place.

2. Remove insert from SmartFence. Using

CLINCHER, move fence forward to a position

where cutter would have profiled the insert

completely through.

3. Clamp a stop block on table top in front of fence

at this position to limit length of travel to protect

inside rear of fence body from damage.

4. Move fence back and re-install blank insert. You

are now ready to make your cut.

CUTTERS WITHOUT BEARINGS

1. First determine the precise height of cutter

through trial and error. This should be done with

insert removed and each sliding section closed to

within

1

/8

”

of cutter.

2. Position fence close to cutter and turn on router

and dust collection system.

3. With

CLINCHER cam handle in the micro-adjust

position, use its thumbwheel to advance fence

until cutter passes completely through insert.

4. Unlock

CLINCHER cam handle. Make several

passes through insert while gently pushing and

pulling fence laterally to slightly enlarge opening.

This will make it easier to use in future setups.

CUTTERS WITH BEARINGS

1. Without an insert, first determine the height of cutter

through trial and error. Measure this height

including bearing and threaded stud. Save your

profiled workpiece for a later setup.

2. Remove cutter from router and install a straight bit

having same diameter as the rub-collar bearing on

the cutter. Set approximately

1

/

16”

higher than your

measurement. Note; A straight bit having a smaller

diameter than bearing may be used by making

offsetting passes to compensate for the difference.

3. Replace blank insert. Loosen both infeed and

outfeed sliding sections and shift the insert to left of

fence centerline by approximately

1

/

64”

. Secure in

place.

4. Cut through insert with straight bit.

5. Shift insert

1

/

64”

to the right side of fence centerline

and cut through insert again to widen the opening.

This procedure should give about

1

/

32”

clearance

around bearing.

6. Realign center of insert to center of fence so that

cutter bearing will be centered to opening.

7. Remove straight bit and replace your cutter. Set to

height established in step 1 by using your scrap

workpiece made during your trial and error setup.

8. Make the final cut of insert with cutter.

9. Using a straight edge, micro-adjust

CLINCHER to

align bearing flush to face of fence insert for your

final setup.

5

1

1

/

4

”

PVC elbow

2” O.D.

1

1

/

2

”

PVC elbow

Female Bushing

2

3

/

4

”

O.D.

X-Y Stop Block & Fence Scales