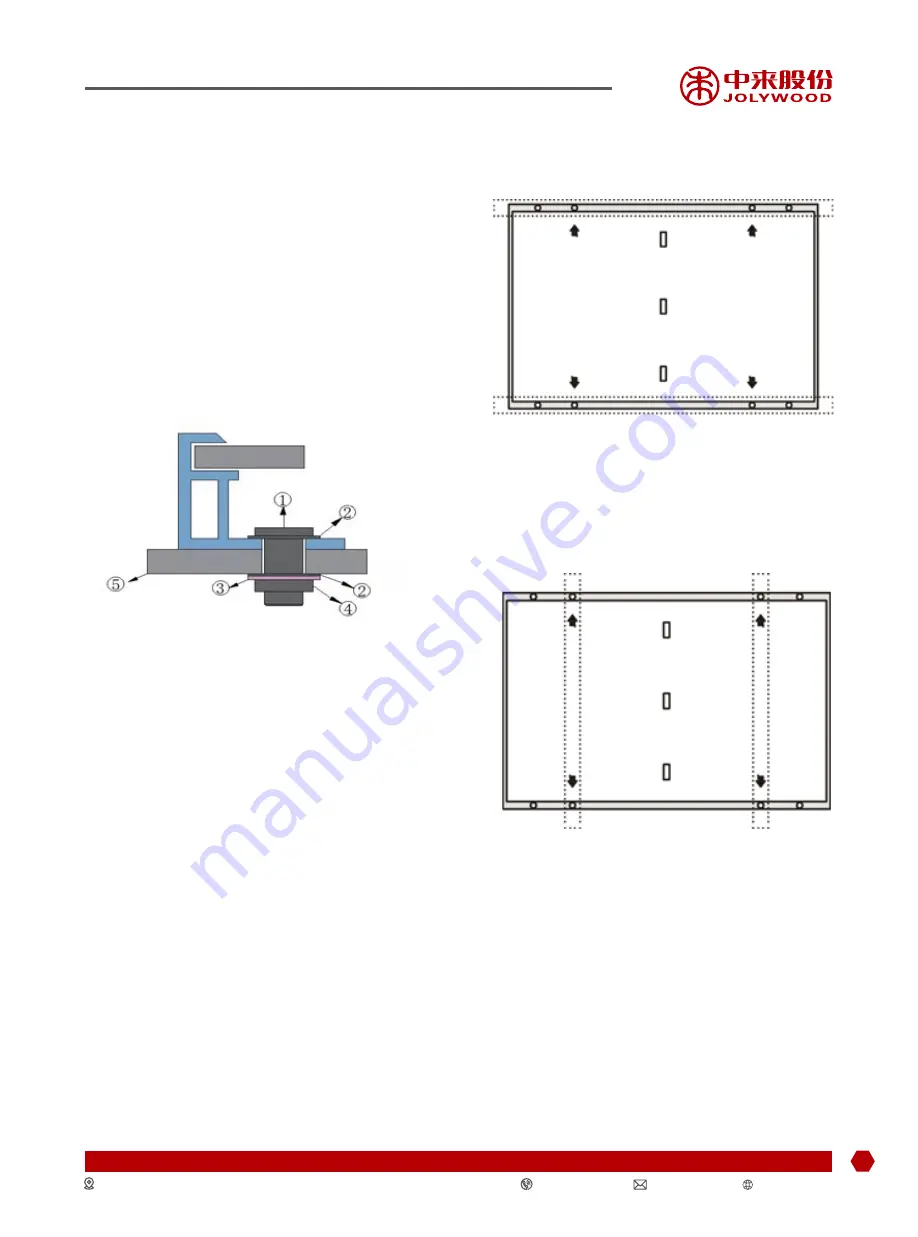

① M8 screw ② Flat washer ③ Spring washer

④ Nut ⑤ Mounting rail

Note: The above standard installation is used

in the Jolywood standard Clamp. For details,

please refer to the Jolywood standard clamp

drawing.

Bolt mounting method:

5.4

Framed Bifacial Double-Glass modules

(installation with bolts)

a) The modules should be bolted to the

support structure using the mounting holes on

the back of the frame.

b) Each modules needs to be fastened by

at least 4 points on two opposite sides.

c) M8 x 1.25 (5/16”) bolts and nuts should

be used. The yield strength of bolts and nuts

should not be less than 450 MPa, and the reco-

mmended torque is 16-20 Newton meters.

d) The outer flat washer needs to use M8

(A2-70), a stainless steel (SUS304) flat washer

with an outer diameter of 20±2 mm and a

thickness of 1.1-1.2 mm; the corresponding

stainless steel spring washer thickness is

2.0±0.2mm.

Bolt:

11

Jolywood (Taizhou) Solar Technology Co.,Ltd.

Kaiyang Rd., Jiangyan Economic Development zone, Taizhou City, Jiangsu Province, P. R. China

www.jolywood.cn

mkt@jolywood.cn

+86-523-8061 2361

All module frames and brackets must

be properly grounded in accordance with

the appropriate National Electrical Code.

The grounding conductor or grounding

5.5

Grounding

Mounted with 4 inner holes along the long frame.

C-shaped steel parallel to the long frame.

Maximum load: front ≤2400pa back ≤2400pa

Mounted with 4 inner holes along the long frame.

C-shaped steel perpendicular to the long frame.

Maximum load: front ≤5400pa back ≤2400pa

Installation Manual

- Jolywood N-type Mono-crystalline Double Glass Module