BULLDOG MINI

1.0

54

Rev.

TROUBLESHOOTING

8. TROUBLESHOOTING

The maintenance work authorized by

BULLDOG

SCRUBBERS

is indicated in section

"7. MAINTENANCE"

.

The content of this chapter is not exhaustive. Instead, it aims to provide information on the

most common problems in order to help specialized technicians to find the fault in question.

CAUTION

The indications under the term “SOLUTION” in the tables below DO

NOT AUTHORISE interventions that could jeopardise safety.

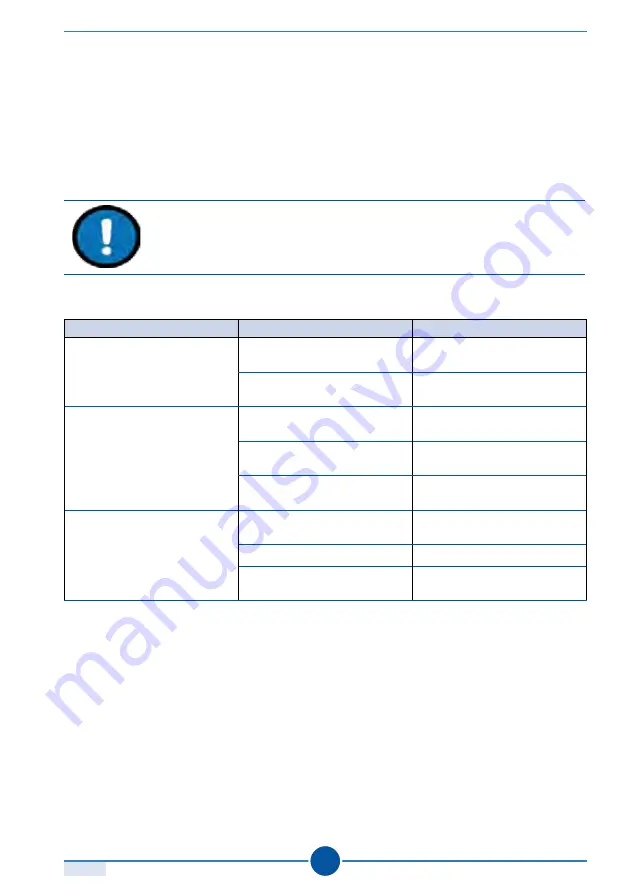

PROBLEM

PROBABLE CAUSE

SOLUTION

Wet stripes on the sides

Irregular paths are covered. Follow the instructions in

chapter

"7. MAINTENANCE"

.

Recovery tank scrapers

dirty or worn.

Clean or replace the

scrapers.

The floor remains wet

The squeegees are dirty or

worn.

Clean or replace the

squeegees.

The suction recovery hose

is clogged.

Clean or replace the

suction hose.

The cap of the suction tank

is positioned incorrectly.

Check and position the

suction tank cap correctly.

The dirt is not picked up

Recovery tank with dirty or

worn scrapers.

Clean or replace.

Worn brushes.

Replace.

Cleaning liquid not coming

out.

Check the water filter.