English---7

115304126 Rev. 2 7/15/10

GENERAL SAFETY PRECAUTIONS

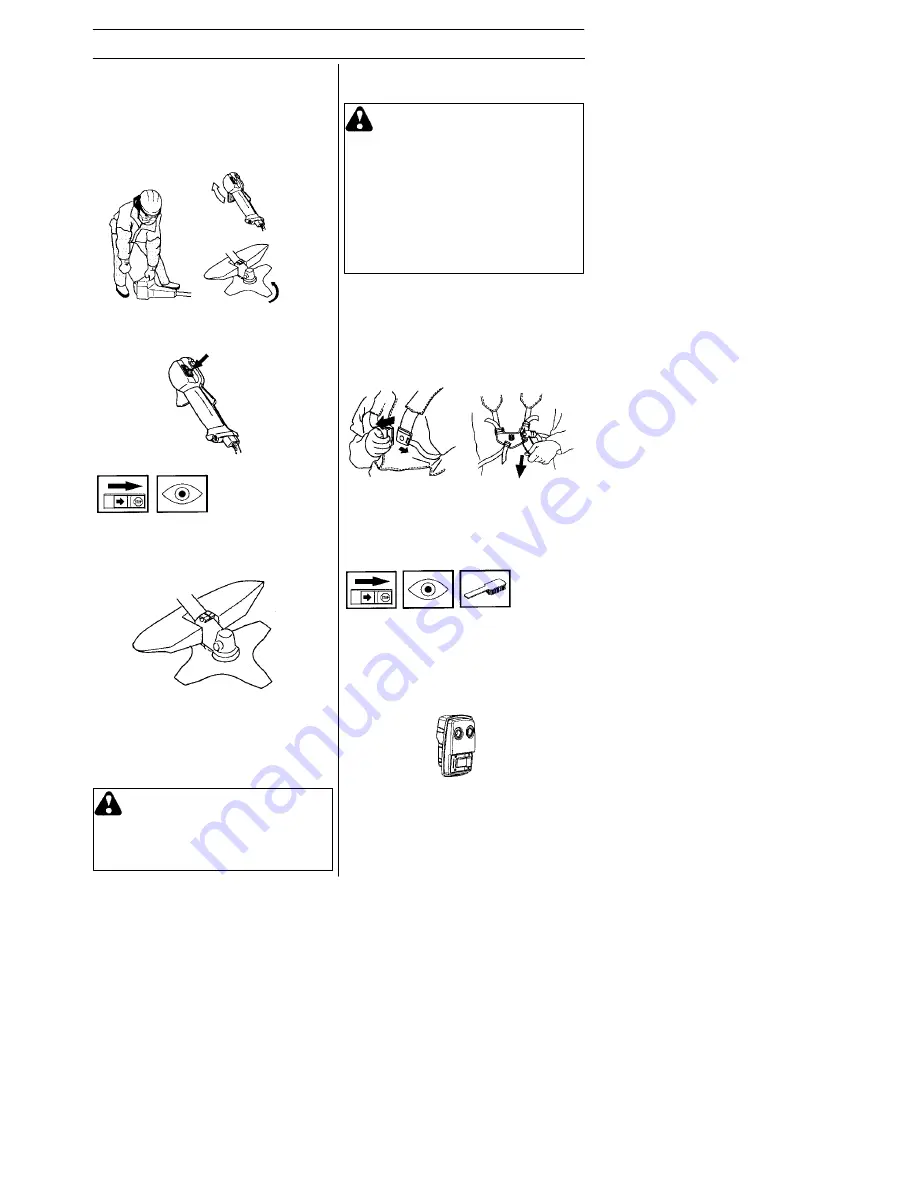

Stop switch

Make sure the engine stops when you push

and hold the stop switch.

Cutting attachment guard

This guard is intended to prevent loose

objects from being thrown towards the

operator. The guard also protects the

operator from accidental contact with the

cutting attachment.

Check that the guard is undamaged and not

cracked. Replace the guard if it has been

exposed to impact or is cracked.

Always use the recommended guard for the

cutting attachment you are using. See the

“Technical data” section.

WARNING:

Never use a cutting

attachment without an approved

guard. See the section on “Technical

data”. If an incorrect or faulty guard

is fitted this can cause serious

personal injury.

WARNING:

Overexposure to

vibration can lead to circulatory

damage or nerve damage in people

who have impaired circulation.

Contact your doctor if you experi-

ence symptoms of overexposure to

vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength,

changes in skin color or condition.

These symptoms normally appear

in the fingers, hands or wrists. The

risk increases at low temperatures.

Muffler

The muffler is designed to reduce the noise

level and to direct the exhaust gases away

from the operator.

CAUTION! Muffler is fitted with a catalytic

convertic designed to reduce harmful ex-

haust gases.

Harness quick release

There is an easily accessible, harness

quick release fitted at the front in case of an

emergency that requires you to free your-

self from the machine and harness.

See instructions under the heading Adjust-

ing the harness.

Check that the harness straps are correctly

positioned. Once the harness and machine

have been adjusted, check that the harness

quick release works correctly.

Use of incorrectly wound trimmer line or an

incorrect cutting attachment increases the

level of vibration.

See instructions under the heading Start.

Start the machine and apply full throttle.

Release the throttle and check that the

cutting attachment stops and remains at a

standstill. If the cutting attachment rotates

with the throttle in the idle position then the

carburettor idle setting must be checked.

See instructions under the heading

Maintenance.