5

OPERATION

WARNING:

Be sure to read the fuel

information in the safety rules before you be-

gin. If you do not understand the safety rules,

do not attempt to fuel your unit. Contact an

authorized service dealer.

FUELING ENGINE

WARNING:

Remove fuel cap slowly

when refueling.

This engine is certified to operate on un-

leaded gasoline. Before operation, gasoline

must be mixed with a good quality synthetic

2-cycle air-cooled engine oil designed to be

mixed at a ratio of 40:1 (2.5%). A 40:1 ratio is

obtained by mixing 5 liters of unleaded gaso-

line with 0,125 liter of oil. DO NOT USE auto-

motive oil or boat oil. These oils will cause en-

gine damage.

When mixing fuel, follow

instructions printed on oil container. Once oil

is added to gasoline, shake container mo-

mentarily to assure that the fuel is thoroughly

mixed. Always read and follow the safety

rules relating to fuel before fueling your unit.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads to

separation and formation of acids during stor-

age. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine

problems, empty the fuel system before stor-

age for 30 days or longer. Drain the gas tank,

start the engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel next

season. Never use engine or carburetor

cleaner products in the fuel tank or permanent

damage may occur.

HOW TO STOP YOUR UNIT

S

To stop the engine, move the ON/OFF

switch to the OFF position.

HOW TO START YOUR UNIT

WARNING:

The trimmer head will

turn while starting the engine. Avoid any con-

tact with the muffler. A hot muffler can cause

serious burns.

STARTING A COLD ENGINE (or a

warm engine after running out of fuel)

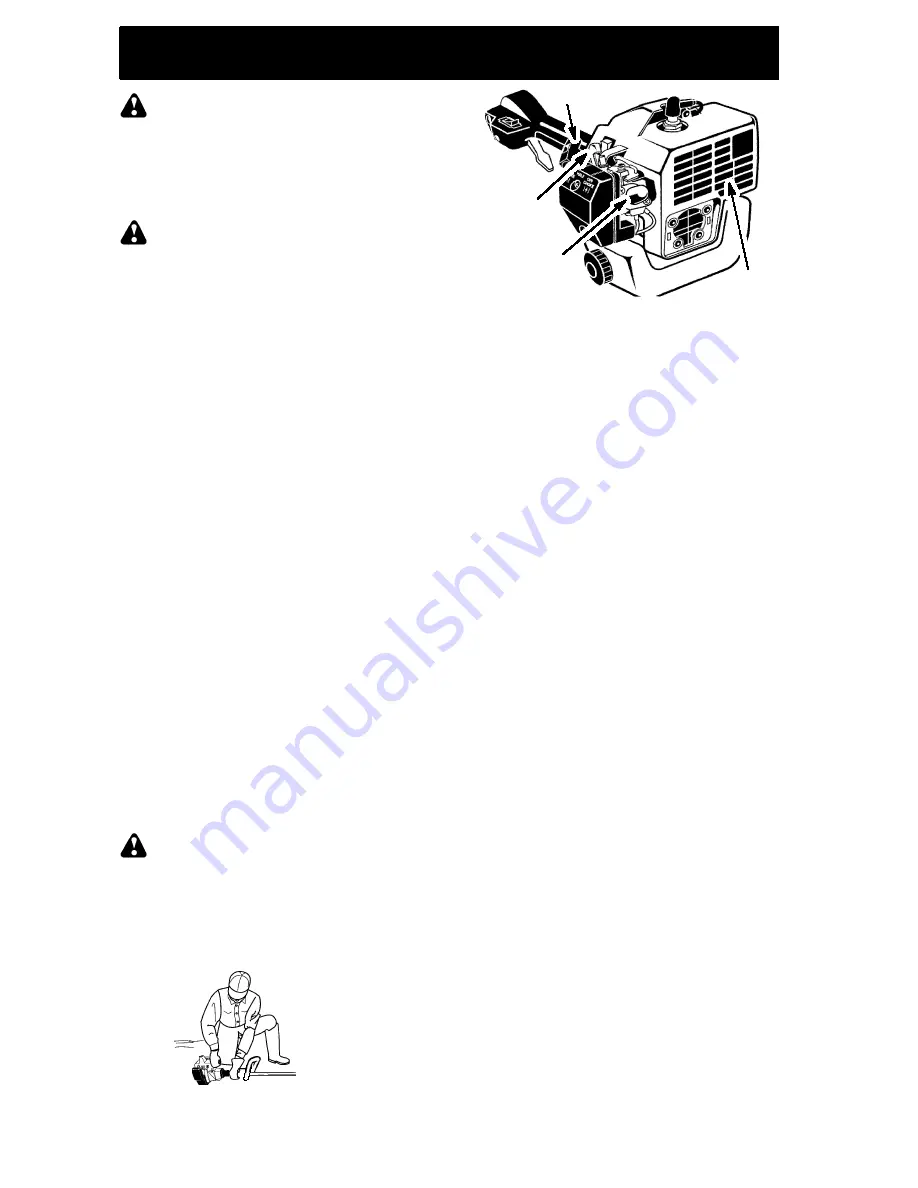

Starting Position

Choke

Lever

Primer Bulb

Starter Handle

Muffler

1. Set unit on a flat surface.

2. Move ON/OFF switch to the ON position.

3. Slowly press the primer bulb 6 times.

4. Move choke lever to FULL CHOKE posi-

tion.

5. Squeeze and hold trigger through

all re-

maining steps

.

6. Pull starter rope handle sharply until en-

gine sounds as if it is trying to start, but do

not pull rope more than 6 times.

7. As soon as engine sounds as if it is trying

to start, move choke lever to HALF

CHOKE.

8. Pull starter rope sharply until engine runs,

but no more than 6 pulls. If the engine

doesn’t start after 6 pulls (at the HALF

CHOKE position), move the choke lever

to the FULL CHOKE position and press

the primer bulb 6 times. Squeeze and hold

the throttle trigger and pull the starter rope

2 more times. Move the choke lever to the

HALF CHOKE position and pull the start-

er rope until the engine runs, but no more

than 6 pulls.

NOTE:

If engine still doesn’t start, it is

probably flooded. Proceed to STARTING

A FLOODED ENGINE.

9. Once the engine starts, allow it to run 10

seconds, then move the choke lever to

OFF CHOKE. Allow the unit to run for 30

more seconds at OFF CHOKE before re-

leasing the throttle trigger.

NOTE:

If engine dies with the choke le-

ver in the OFF CHOKE position, move the

choke lever to the HALF CHOKE position

and pull the rope until engine runs, but no

more than 6 pulls.

STARTING A WARM ENGINE

1. Move ON/OFF switch to the ON position.

2. Move the choke lever to the HALF

CHOKE position.

3. Squeeze and hold the throttle trigger.

Keep throttle trigger fully squeezed until

the engine runs smoothly.

4. Pull starter rope sharply until engine runs,

but no more than 5 pulls.

5. Allow engine to run 15 seconds, then

move the choke lever to the OFF CHOKE

position.