6

NOTE:

If engine has not started, pull starter

rope 5 more pulls. If engine still does not run, it

is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing

the choke lever in the OFF CHOKE position;

then, pull the rope to clear the engine of ex-

cess fuel. This could require pulling the starter

handle many times depending on how badly

the unit is flooded.

If the unit still doesn’t start, refer to TROU-

BLESHOOTING TABLE.

OPERATING INSTRUCTIONS

For occasional use only.

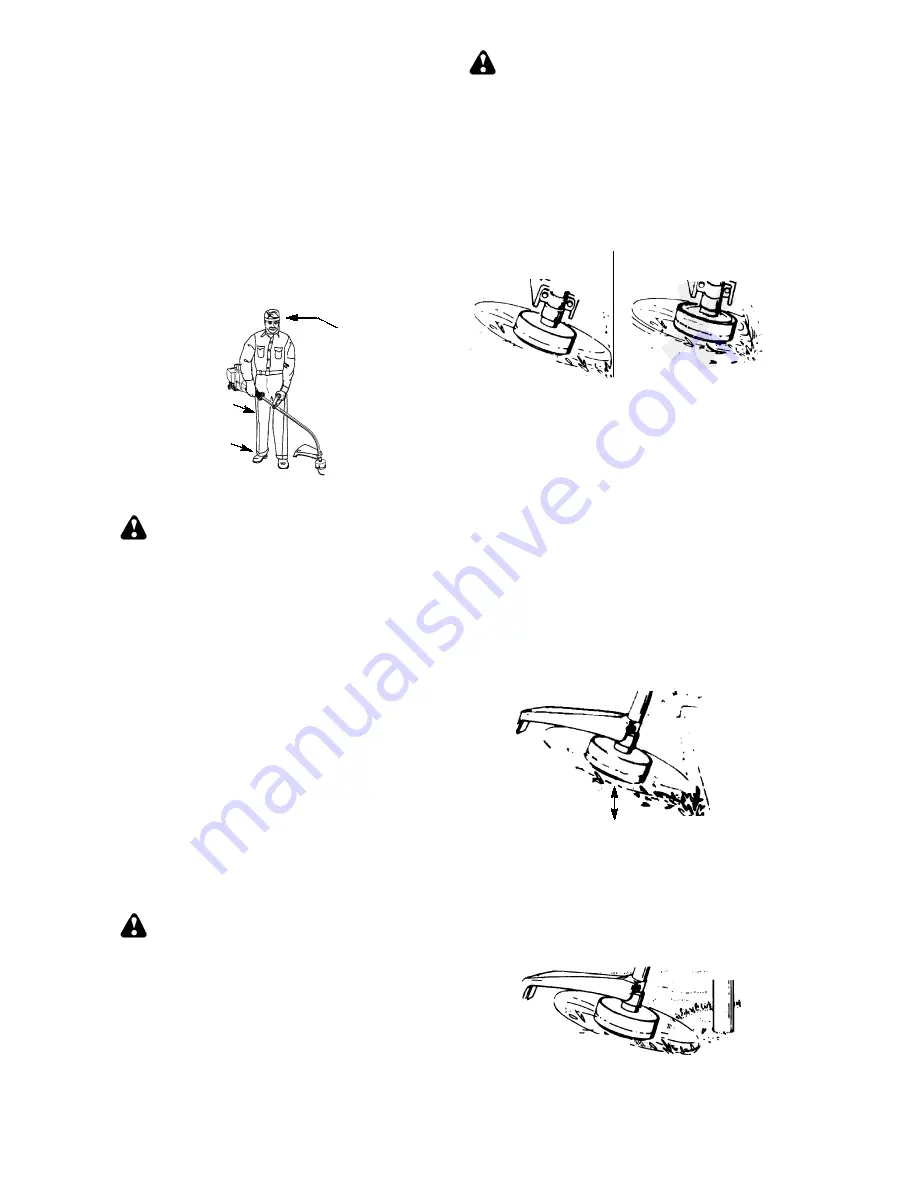

OPERATING POSITION

Eye Protection

Long Pants

Heavy Shoes

ALWAYS WEAR:

Cut from your right to your left.

WARNING:

Always wear eye protec-

tion and hearing protection. Never lean over

the trimmer head. Rocks or debris can rico-

chet or be thrown into eyes and face and

cause blindness or other serious injury.

Do not run the engine at a higher speed than

necessary. The cutting line will cut efficiently

when the engine is run at less than full throttle.

At lower speeds, there is less engine noise and

vibration. The cutting line will last longer and will

be less likely to “weld” onto the spool.

Always release the throttle trigger and allow the

engine to return to idle speed when not cutting.

To stop engine:

S

Release the throttle trigger.

S

Move the ON/OFF switch to the OFF posi-

tion.

TRIMMER LINE ADVANCE

Advance line by tapping the bottom of the cut-

ting head lightly on the ground while engine is

running at full speed. The metal line limiter

blade attached to the guard will cut the line to

the proper length.

WARNING:

Use only 2 mm diameter

line. Other sizes and shapes of line will not ad-

vance properly and will result in improper cut-

ting head function or can cause serious injury.

Do not use other materials such as wire,

string, rope, etc. Wire can break off during

cutting and become a dangerous missile that

can cause serious injury.

CUTTING METHODS

WARNING:

Use minimum speed and

do not crowd the line when cutting around

hard objects (rock, gravel, fence posts, etc.),

which can damage the trimmer head, become

entangled in the line, or be thrown causing a

serious hazard.

S

The tip of the line does the cutting. You will

achieve the best performance and mini-

mum line wear by not crowding the line into

the cutting area. The right and wrong ways

are shown below.

Tip of the Line

Does The Cutting

Right

Wrong

Line Crowded Into

Work Area

S

The line will easily remove grass and

weeds from around walls, fences, trees and

flower beds, but it also can cut the tender

bark of trees or shrubs and scar fences.

S

For trimming or scalping, use less than full

throttle to increase line life and decrease

head wear, especially:

S

During light duty cutting.

S

Near objects around which the line can-

wrap such as small posts, trees or fence

wire.

S

For mowing or sweeping, use full throttle for

a good clean job.

TRIMMING -- Hold the bottom of the trimmer

head about 80 mm above the ground and at

an angle. Allow only the tip of the line to make

contact. Do not force trimmer line into work

area.

Trimming

3 in. (8 cm)

Above Ground

SCALPING -- The scalping technique re-

moves unwanted vegetation. Hold the bottom

of the trimmer head about 80 mm above the

ground and at an angle. Allow the tip of the line

to strike the ground around trees, posts,

monuments, etc. This technique increases

line wear.

Scalping