6

Servicing and testing

6.1

Servicing instructions

The skid plate on the semi-trailer that engages with the fifth wheel

coupling must meet the following conditions to provide a long service

life and trouble-free function:

Max. 2 mm unevenness

Adequate reinforcement must be assured

Smooth and groove-free surface if possible, without weld

bumps (smooth existing groove burr)

Rounded or chamfered front and side edges

Complete coverage of the fifth wheel coupling support area.

ATTENTION!

Effective lubrication of the top of the fifth wheel coupling

plate (apart from on the W version), the locking mecha-

nism, the pivot bearings (only for the D version) and the

king pin (before using for the first time and after cleaning)

is essential to ensure their long service life. In the W ver-

sion, we recommend applying a thin coat of grease to the

skid plate.

ADVICE!

Before installation, the skid plate must be checked to en-

sure it is even, and the skid plate thickness must also be

checked. The unevenness of the skid plate must be no

more than 2 mm in the load-bearing section of the fifth

wheel coupling. The skid plate must cover the fifth wheel

coupling's set-down surface in every position.

6.1.1 Fifth wheel coupling with manual lubrication

At short intervals, at the latest every 5,000 km:

Uncouple the semi-trailer

Clean the fifth wheel coupling and the skid plate.

Grease the fifth wheel coupling plate, locking mechanism parts

and king pin with high-pressure grease (EP), JOST high-per-

formance lubricant (article no. SKE 013 440 000).

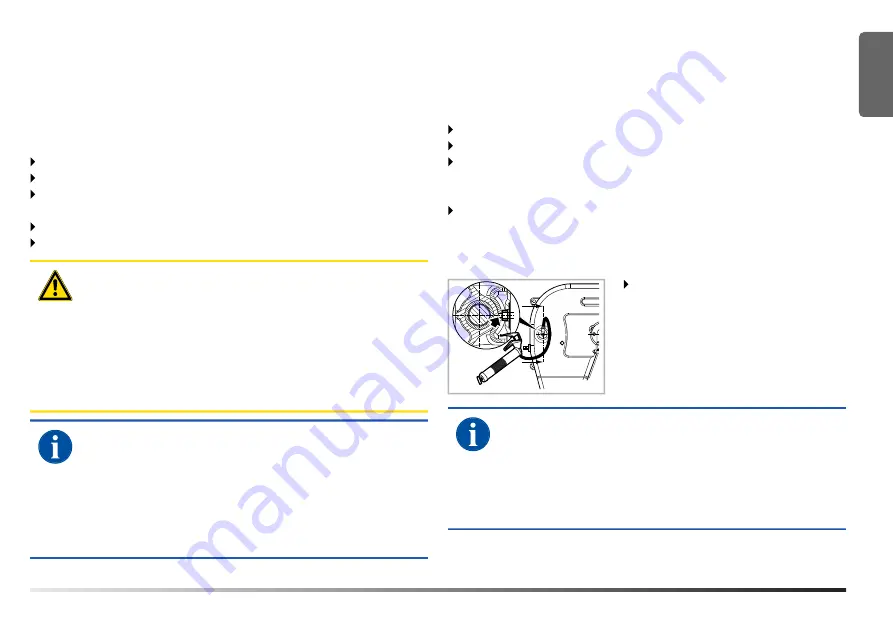

Grease the pivot bearing of version D via the hole on the

top part of the plate (see Figure G50/27) with

paste-like

high-

pressure grease (EP), JOST high-performance lubricant

(article no. SKE 013 440 000).

G50/27

Grease the pivot bearing of ver-

sion D on both sides (lubrication

adapter SKE 013 440 000).

ADVICE!

The pivot bearings on the C and E versions require no

servicing. The grease nipples on the edge of the fifth

wheel coupling plate are only designed for additional

greasing of the locking mechanism between service in-

tervals.

EN

JSK 36 & JSK 37

MUB 002 004 M01

(REV-C)

04-2019

15

JOST IND (REV-A) 06-2019

JSK 39

Summary of Contents for JSK 39

Page 26: ......