6

Servicing and testing

6.3

Test instructions

Depending on the conditions of use, but no later than every 50,000

km or every six months, the fifth wheel coupling, the mounting plate,

the slider and the king pins should be checked for:

Function

Wear

Correct position of the fastening elements (check prescribed

torque values)

Damage or distortion

Cracks

Corrosion

To ensure adequate lubrication

To ensure the smooth running of the mechanisms

and repaired where necessary (see the appropriate JOST repair in-

structions at www.jost-world.com).

6.4

Wear test

Fifth wheel couplings and king pins are subject to more or less wear

depending on the conditions in which they are used, and this wear

is noticeable by play towards the front of the vehicle. Excessive play

causes shocks and may lead to instability on the road and damage to

the fifth wheel coupling, mounting plate, sliders and vehicle chassis.

JOST fifth wheel couplings have a manual infinite adjustment facility

for the locking mechanism to extend their service lives.

ATTENTION!

The wear on the king pin must not be compensated for

through adjustment.

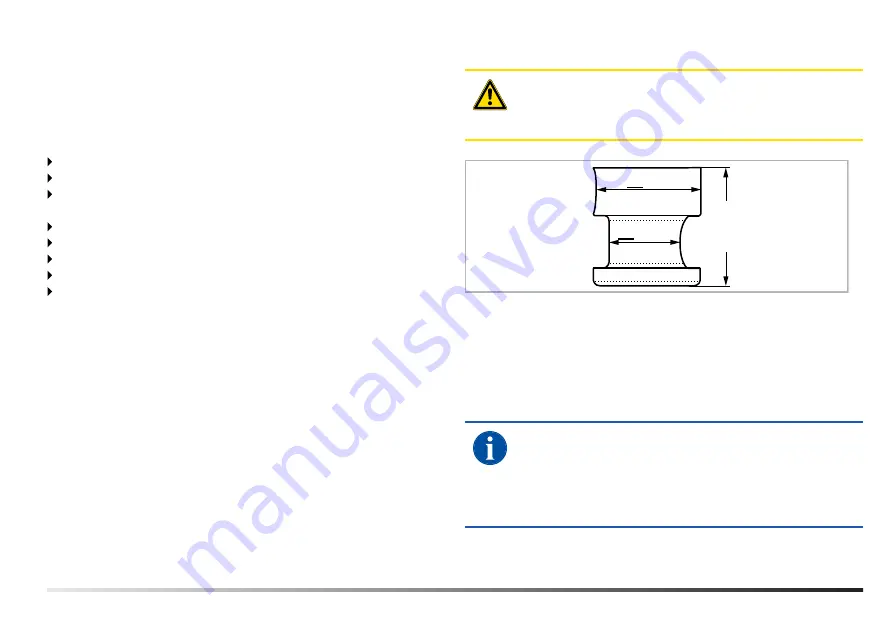

71

-73 mm

84-82.5 mm

49

-50.8 mm

JSK40/05

When the wear limit on the king pin has been reached, it must be

replaced. After the king pin has been replaced, the locking mecha-

nism must be adjusted again.

Play caused by wear on the king pin should either be accepted if

within the permitted wear limit for the king pin (see Figure JSK 40/05)

or should be rectified by fitting a new king pin.

ADVICE!

After work on the locking mechanism or after replace-

ment of the lock jaw, wearing ring or locking bar, the lock-

ing mechanism must always be readjusted in order to en-

sure the base clearance of 0.3 mm.

20

MUB 002 004 M01

(REV-C)

04-2019

JSK 36 & JSK 37

JOST IND (REV-A) 06-2019

JSK 39

& tear(wearing ring, lock jaw, locking bar & rubber bush,etc.)

Summary of Contents for JSK 39

Page 26: ......