5

Maintenance

5.1

Inspection instructions

When containers are tipped, locks – particularly at the rear – are

subjected to greater wear than during simple transport; there is

also a considerably greater risk of accident due to component fail-

ure.

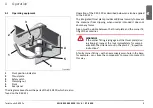

WARNING!

If locks are faulty, the higher forces exerted while tipping

pose a risk of the container falling off. Therefore, replace

faulty parts with genuine spare parts immediately.

ADVICE!

You or the operator must visually inspect all locks to

ensure they are complete, undamaged and in perfect

working order

every day before driving commences

.

At least every six weeks, have the following tests performed by a

qualified specialist:

Housing

Function test of internal lock parts (all operating positions

described in the instructions for use can be reached).

Check housing for abnormal deformation (minor deformation

due to operation, e.g. of the upper panel, is admissible).

Check guide bush for deformations that adversely affect func-

tion (the pivot can be clamped between the two cams of the

guide bush with the clamping nut without problem).

Check for visible cracks.

Safety catch

Check that the safety catch is present, is not damaged and

functions correctly (when tightened, the clamping nut is

secure so it cannot work loose).

EN

Twist Locks R 403 Fx

MUB 013 005 M30

(REV-B)

07-2020

13