Summary of Contents for JNSZ1100SVB

Page 6: ...Warranty policy...

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 41: ...13 ENGINE WIRING DIAGRAM...

Page 96: ...95 46 ELECTRIC INJECTION SYSTE...

Page 97: ...96...

Page 98: ...97...

Page 99: ...98...

Page 100: ...99...

Page 101: ...100...

Page 102: ...101...

Page 103: ...102...

Page 104: ...103...

Page 105: ...104...

Page 106: ...105...

Page 107: ...106...

Page 108: ...107...

Page 109: ...108...

Page 110: ...109...

Page 111: ...110...

Page 112: ...111...

Page 113: ...112...

Page 114: ...113...

Page 115: ...114...

Page 116: ...115...

Page 117: ...116...

Page 118: ...117...

Page 119: ...118...

Page 120: ...119...

Page 121: ...120...

Page 122: ...121...

Page 123: ...122...

Page 124: ...123...

Page 125: ...124...

Page 126: ...125...

Page 127: ...126...

Page 128: ...127...

Page 129: ...128...

Page 130: ...129...

Page 131: ...130...

Page 132: ...131...

Page 133: ...132...

Page 134: ...133...

Page 135: ...134...

Page 136: ...135...

Page 137: ...136...

Page 138: ...137...

Page 218: ...217 4 Attach tie rod and front wheel...

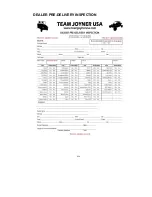

Page 225: ...224 DEALER PRE DELIVERY INSPECTION...