FAA Approved Installation Manual for the

Report No 908

EDM-900 and EDM-930

Page 15 of 55 Rev I

Primary Engine Data Management System

Date 1-18-2013

15.

Cylinder Head Temperature (CHT) Probe Installation

Use the J2 connector harness 700700 or 700702 labeled C1 through C4 or C6. The JPI probe is a bayonet probe

P/N 5050-T that has a captive 3/8-24 boss that is screwed into the head of each cylinder.

For Indicator replacement, replace your existing CHT probe and adapter, a bayonet or screw in type with one

supplied by JPI. Install the probe on the same cylinder from which you removed the original equipment probe. Your

current CHT probe is installed in the hottest cylinder as determined by the airframe manufacturer.

16.

Radial Engine CHT (spark plug gasket)

Cylinder head temperatures are measured with a spark plug gasket type probe placed under the front sparkplugs.

Front spark plugs will read 15 to 20 degrees cooler than the rear plugs. The spark plug gasket probe, P/N M-113,

replaces the standard copper spark plug gasket on one spark plug. The probe is usually placed on the plug that

receives the most direct cooling air. After many removals the probe may be annealed for re-use. Heat to 1100

o

F

and quench in water.

17.

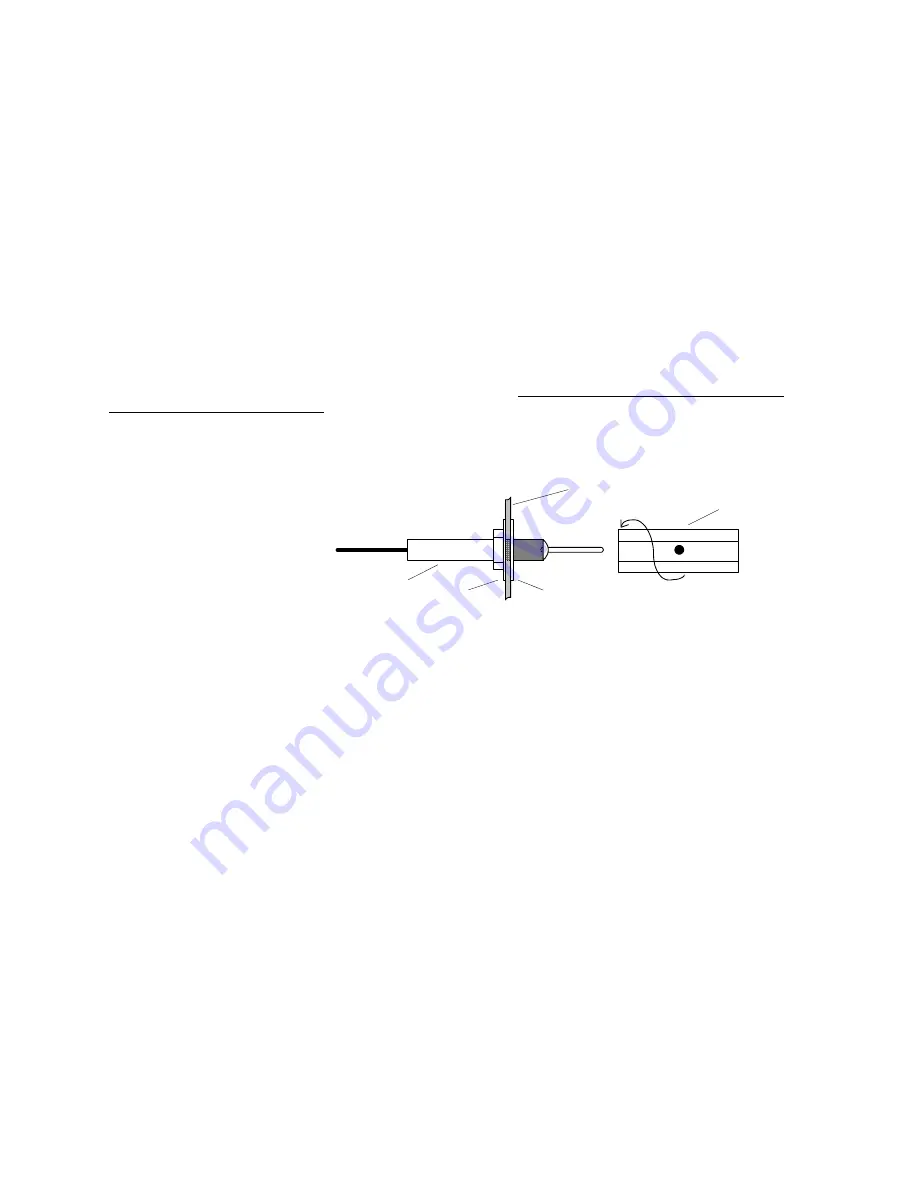

Outside Air Temperature (OAT) Probe Installation

Use the J1 connector harness

790200 labeled OAT. All wiring

must be type K thermocouple

wire. Do not splice ordinary

copper wire in any temperature

probe circuits.

Install the OAT probe, PN 400510

in the airframe manufacturer’s

recommended location. If this information is not available, place the OAT probe in clean airflow such as in a cabin

air scoop or below the underside of the wing away from engine heat or exhaust. In this case it is recommended that

the installation be done similar to the antenna installation instructions of AC 43.13-2b

Acceptable Methods,

Techniques and Practices

.

The outside aluminum shield tube is used to both hold the probe in place and shield it from radiated heat from the

sun. The OAT option is displayed as an independent digital temperature bar graph such as "75.”

18.

Induction Air (IAT), Compressor Discharge Temperature Probe Install (optional)

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 3 and the red wire into pin

4. All wiring must be type K thermocouple wire. The Induction Air Temperature probe, (IAT), is installed just after

the inter-cooler and the Compressor Discharge Temperature (CDT) just before the inter-cooler. The probe is the

same as an EGT probe and installed similarly to an EGT probe. A large clamp is supplied to fit around the air duct

leaving the inter-cooler. Alternately a 1/8 NPT fitting is available. IAT option is displayed as an independent digital

temperature like "125 IAT". On non-turbo engines the IAT in reality is the Carburetor temperature and displayed as

“34 CRB.”

19.

Carburetor Probe Installation (optional)

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 5 and the red wire into pin

6. All wiring must be type K thermocouple wire. Do not splice ordinary copper wire in any temperature probe

circuits. Locate the access hole (1/4-24 thread) in the carburetor near the butterfly valve. Remove the screw plug

now in that hole and screw the CRB probe into the carburetor throat. No drilling or machining of the carburetor is

necessary.

20.

Oil Temperature Probe Installation

The sensor port is a standard 5/8-18 thread for both the Continental and Lycoming engines. Probe PN 400509 is a

complete assembly using type K thermocouple wire (red/yellow). Connect the wire marked oil temperature

washer

aircraft sheet metal

washer

probe

shield tube

used to secure

probe