65

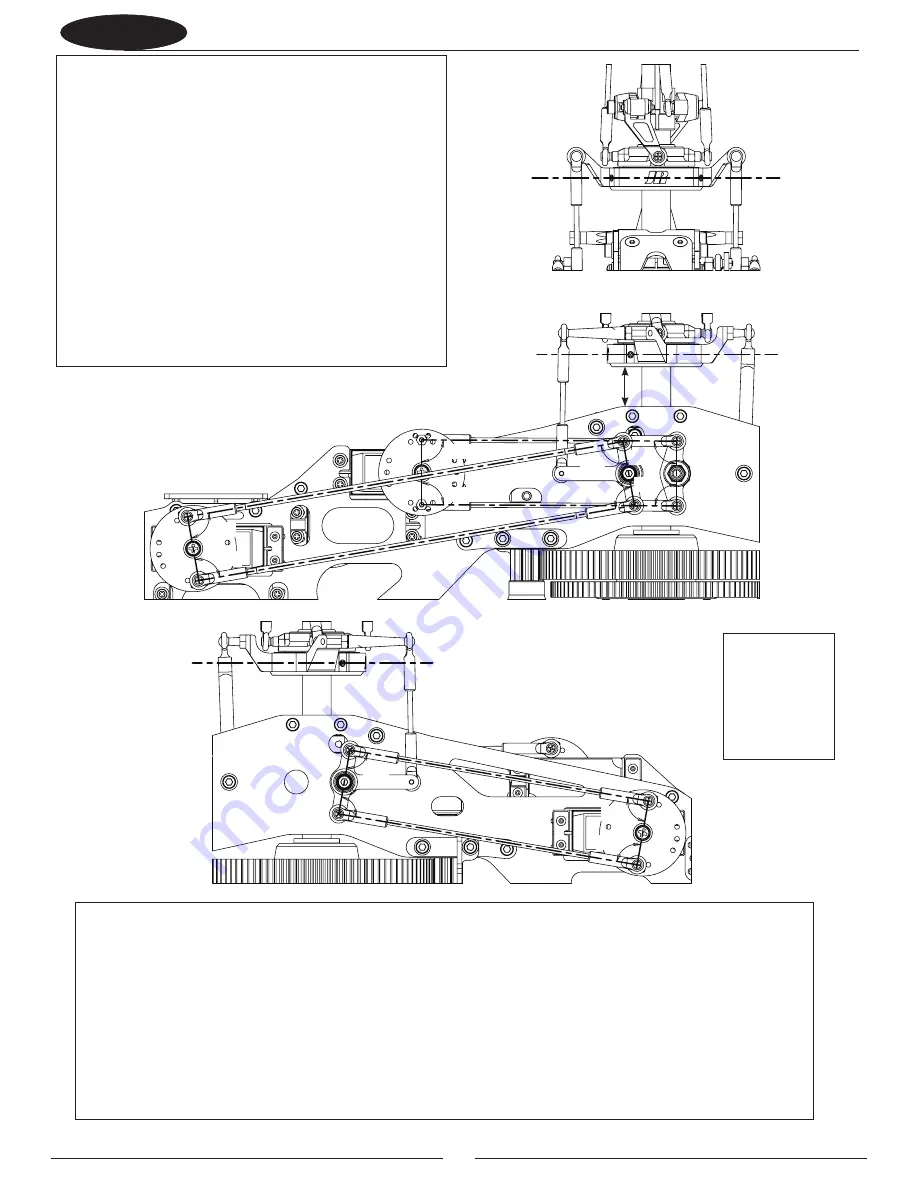

After the control linkages have been attached to the

swashplate, it will be necessary to check the swashplate to

ensure that it is level. To do this, turn on the radio system and

place the collective stick in the center position as before. Next,

check to make sure that all trim levers and knobs are also in

their center position. Check to ensure that the servo arms are

parallel to the servos as adjusted in the previous step. If the

servos are not parallel, please adjust the sub trim function in

the radio system as necessary. Once it’s determined that the

servo arms are parallel to the servos as required, it will now be

necessary to check the swashplate to ensure that it is also level

or neutral in this position. It is suggested that the swashplate

first be checked from the rear of the model to ensure that

it’s level from left to right. If the swashplate is not level as

compared to the frame of the model, adjust either the left or

right servo control rods as needed.

To determine which rod needs adjustment, it may be helpful to view the swashplate from the left and right side view of

the model to determine which side is high or low. Once this left to right adjustment is completed, it will now be necessary

to check the fore/aft position of the swashplate to ensure that it is also level on this axis. If the swashplate is not level

in the fore/aft axis, it is suggested that the adjustment be made to the front servo control linkage as needed by slightly

repositioning the elevator control arm on the elevator a-arm assembly, or adjusting both front servo control rods. If you

are unsure as to which linkage needs adjustment or are having

obtaining the correct adjustment, please check

the length of each control rod to ensure that it is adjusted to the correct length.

Only minor adjustments should be made to the lengths of the control linkages at this time. Any major adjustments

indicate either incorrect linkage lengths or incorrect servo arm positioning. If the control linkage lengths are altered

from the recommended lengths more that one or two turns, this will have a great effect on the range and settings of the

collective pitch in later steps.

6-5

CHECKING THE SWASHPLATE FOR LEVEL

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

After the control linkages have been attached to the swashplate,

it will be necessary to check the swashplate to ensure that it is

level. To do this, turn on the radio system and place the collective

stick in the center position as before. Next, check to make sure

that all trim levers and knobs are also in their center position.

Check to ensure that the servo wheels are centered as shown. If

the servos are not centered as shown, please adjust the sub trim

function in the radio system as necessary. Once it’s determined

that the servo wheels are centered properly, it will now be

necessary to check the swashplate to ensure that it is also level

or neutral in this position. It is suggested that the swashplate

first be checked from the rear of the model to ensure that it’s

level from left to right. If the swashplate is not level as compared

to the frame of the model, adjust either the left or right servo

control rod as needed.

Once the left to right adjustment is completed, it will now be necessary to check the fore/aft position of the swashplate to

ensure that it is also level on this axis. If the swashplate is not level in the fore/aft axis, it is suggested that the adjustment

be made to the rear servo control linkage as needed by slightly repositioning the elevator control arm on the elevator

A-arm assembly, or adjusting both front servo control rods. If you are unsure as to which linkage needs adjustment or are

having difficulty obtaining the correct adjustment, please check the length of each control rod to ensure that it is adjusted

to the correct length. Only minor adjustments should be made to the lengths of the control linkages at this time. Any major

adjustments indicate either incorrect linkage lengths or incorrect servo arm positioning. If the control linkage lengths are

altered from the recommended lengths more than one or two turns, this will have a great effect on the range and settings of

the collective pitch in later steps. If required, use sub trims of each servo to fine-tune 90 degree positions of the linkages. No

more than 15pts should ever be required, since the servo arm can be flipped and a different spline can be used.

17mm

17mm between

bottom of

Swashplate and

top of Frame at

Zero pitch, all

servos neutral.

Summary of Contents for Vibe 90SG

Page 77: ...77 ...

Page 105: ...105 ...