23

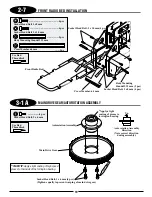

3-7

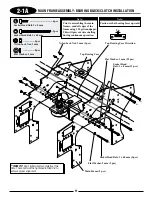

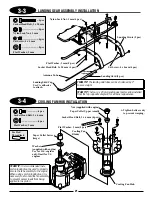

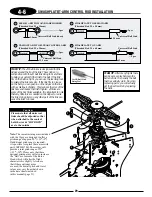

COOLING FAN SHROUD BRACKET ATTACHMENT

Self Tapping Screw, 3 x 12 mm

Self Tapping Screw, 3 x 12 mm (8 pcs)

Cooling Fan Shroud Brackets (2 pcs)

Flat Washer, 3 mm

Flat Washer, 3 mm (8 pcs)

.............8 pcs

.........................8 pcs

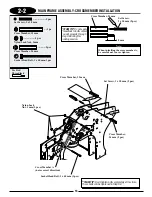

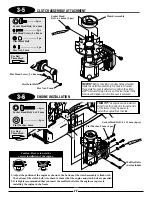

3-8

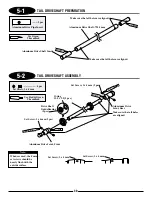

BOLT TIGHTENING ORDER/GEAR MESH ADJUSTMENT

Bolt Tightening Order:

1. Motor Mount to Main Frame Plates

2. Start Shaft Bearing Block/Bearing Blocks “A” & “B”

3. Crossmember “A”, and front Crossmember “B” to Main Frame Plates

4. Upper Main Shaft Bearing Block to Main Frame Plates

5. Rear Crossmember “B” to Main Frame Plates

6. Tighten all remaining bolts on frame left loose from Steps 2-1, 2-2, and 2-4

2

5

4

*

*

*

Do not tighten screws at this

time. They will be tightened in

Step 3-9.

Note:

6

Tighten all

remaining bolts.

Use Red

Threadlock

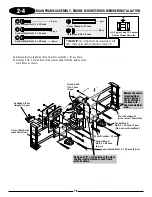

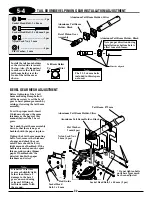

Once the engine has been installed, adjust the gear mesh of

the main pinion so that a slight amount of “backlash” is

achieved. One method for achieving the proper clearance is to

insert a folded piece of paper between the two gears, press the

gears together, then secure the bearing blocks in place. When

setting the gear mesh, make sure that the pinion gear remains

parallel to the main drive gear teeth, as it is possible to alter the

pinion gear angle during adjustment.

If you find difficulty achieving proper alignment of the

pinion, it is also possible to loosen the six bolts that attach the

engine mount to the main frame. This will allow the engine/

mount to be repositioned to achieve the proper gear mesh.

Once the desired gear mesh has been achieved, tighten all

loose bolts from Step 2-1. Please remember to use thread-lock

on the bolts securing the upper start shaft pinion block.

Please also remember to apply threadlock and tighten the

two 3 x 14 mm socket head bolts that connect bearing block

“A” to bearing block “B” . (see Step 1-1 for details).

Gear Mesh Adjustment

1

3

TEAM TIP:

Once the gear mesh/engine alignment

has been established, rotate the start shaft assembly

first counterclockwise, then clockwise. When moved

clockwise, the start shaft assembly should move

freely with little or no resistance. If resistance is

present, the clutch/start shaft assembly are not

aligned properly. Readjust as necessary.

Summary of Contents for Vigor CS

Page 64: ...64 E A C D G F DECAL PLACEMENT ...

Page 65: ...65 B 3 2 5 1 DECAL PLACEMENT ...