Now that the radio system is completely installed into the helicopter, it’s

necessary to check and adjust the following:

1. Servo Direction (Servo Reversing)

Check to insure that all servos have been set to the correct direction as

shown in the Control Linkage Installation section.

2. Dual Rates

It’s suggested that for initial flights, the dual rate function values be

set as follows:

0 Position (low rate) 90%

1 Position (high rate) 100%

3. Exponential Settings

It’s suggested that the exponential rate settings remain in the 0 value

position until the initial test flights. After initial flights, adjust the

exponential values to achieve the desired control feel.

4. Sub-Trim Settings

It’s suggested that the correct neutral settings be achieved without the

use of the Sub-Trim function, as this will affect the neutral position of the

servos. Adjust the cyclic trim using the control rods until a neutral hover

is achieved.

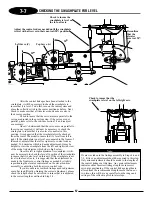

5. Pitch/Throttle Curve Adjustment

It is very important the throttle and pitch curves are adjusted properly to

achieve the best performance from your helicopter. When properly adjusted,

the main rotor head rpm should remain consistent throughout all

maneuvers and throttle stick positions. A constant rpm will also help to

improve the effectiveness and accuracy of the tail rotor and gyro systems.

A) Pitch Curve

It will now be necessary to establish the maximum pitch

value required for your application prior to adjustment. For

example, if you are a 3D pilot, then your maximum negative

pitch will be -10, and your maximum positive pitch will be +11.

The maximum pitch range that you will require will be 21° total.

The maximum pitch range mentioned above must be

established through the use of the pitch travel value in the CCPM

function. As mentioned previously, do not try to establish the

maximum pitch curve values through adjustment of the travel

adjustment function, as this will alter the pitch-to-aileron and

pitch-to-elevator travel values established in Steps 7-8 and 7-9.

Please refer to the CCPM activation section (page 46) for

information on how to access the CCPM function.

Once the CCPM function has been activated, set the

maximum positive pitch settings as mentioned above. Since the

CCPM function does not allow for independent travel settings for

positive and negative pitch, it will be necessary to establish the

maximum positive pitch, since this is generally the largest degree

of pitch in the pitch range. Once the maximum positive pitch

range is set, the maximum negative pitch range can be reduced as

needed through the pitch curve function.

Set the main rotor pitch gauge to the desired maximum pitch

setting, then increase or decrease the CCPM pitch travel (labeled

Pitch or Ch6) as needed until this pitch setting is achieved.

Once this procedure has been completed, the positive and

negative pitch settings for each flight mode can be adjusted

through the radio’s pitch curve function. Please refer to your

radio’s instruction manual for more information.

60

FINAL SERVO ADJUSTMENT AND RADIO SETUP

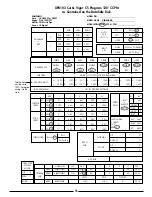

0°

-9°

1°

Normal

(Hover)

Stick Position

Low 1/4

1/2

3/4

High

Stick Position

Stick Position

Flight Mode 1

3D Stunt 1

Autorotation

(Throttle Hold)

Flight Mode 2

3D Stunt 2

(Duplicate of #1)

Pitch Curve Settings

Pitch Range

+11.5°

0°

-9°

-9°

Low 1/4

1/2

3/4

High

Pitch Range

+11°

0°

-9°

Low 1/4

1/2

3/4

High

Pitch Range

+11.5°

-9°

1°

2°

4°

3°

2°

3°

4°

Flight Application

Low Pitch Hovering Pitch High Pitch

Mode

(Low Stick)

(Half Stick)

(High Stick)

N

Hovering

-9°

+5°

+10°

I

3D Flight #1

-9°

+5°

+11°

*2

3D Flight #2

-9°

+5°

+11°

H

Autorotation

-9°

+5°

+11.5°

Pitch Range Settings

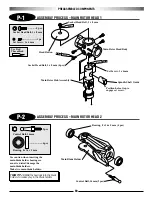

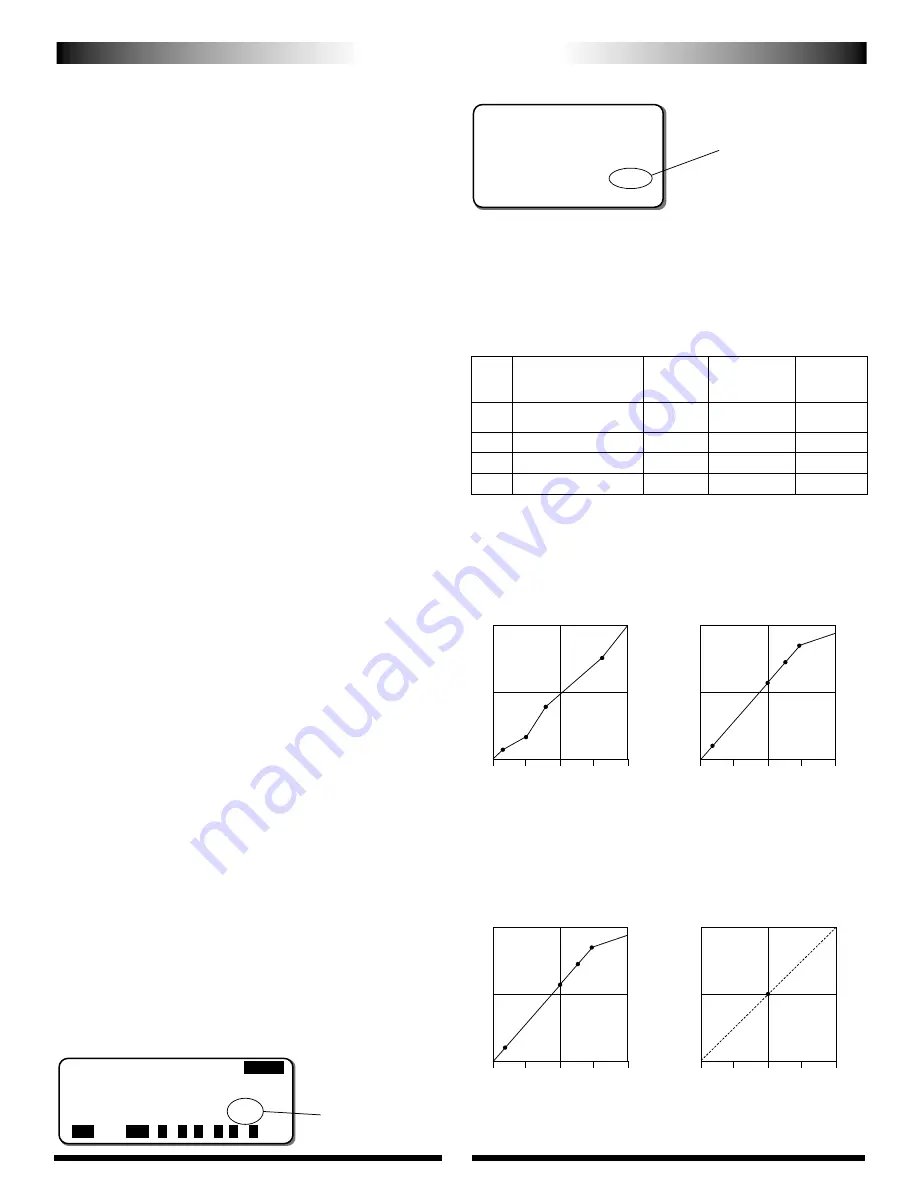

[SWASH

TYPE]

3SERVOS(120•)

EXP

AILE

ELEV

PITCH

+48 +52

+60

ENTER

SEL

ACT

+

–

CL

+

–

CL

+

–

CL

Increase or decrease

the value as needed.

Increase or decrease

the value as needed.

[SWASH MIX]

3servos

120

•

XP8103 System

PCM 10 Series

AILE

+48%

ELEV

+52%

∞ PIT.

+60%

Note:

Flight modes #1 and #2 are duplicated for safety.

Stick Position

0°

-9°

-9°

Low 1/4

1/2

3/4

High

Pitch Range

+11°

1°

2°

4°

3°

1

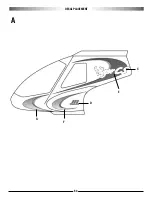

Summary of Contents for Vigor CS

Page 64: ...64 E A C D G F DECAL PLACEMENT ...

Page 65: ...65 B 3 2 5 1 DECAL PLACEMENT ...