82

JRP980027

JRP980035

JRP980026

JRP996007

JRP970004

JRP970004

JRP980056

JRP980105(L80)

JRP980013

JRP996043

JRP980004

JRP970211

JRP980102

JRP996042

JRP980052

JRP994021

JRP970209

JRP980040

JRP980071

JRP994020

JRP980004

JRP980039

JRP994018

JRP980013

JRP970001

JRP991003

JRP980057(L95)

JRP970001

JRP996040

JRP970001

JRP970002

JRP980020

JRP970206

JRP996041

JRP980148

JRP980037

JRP970104

JRP980022

JRP970018

JRP980039

JRP970053

JRP970002

JRP994019

JRP970201

JRP996039

JRP980016

JRP970078

JRP970004

JRP980046

JRP980002

JRP970020

JRP996038

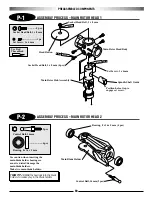

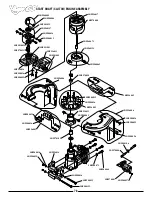

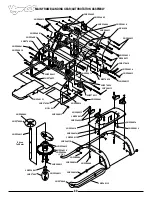

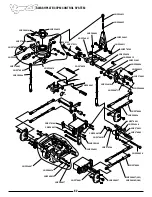

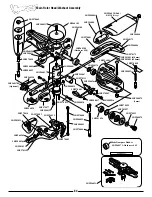

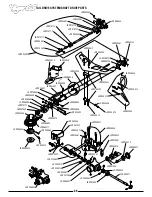

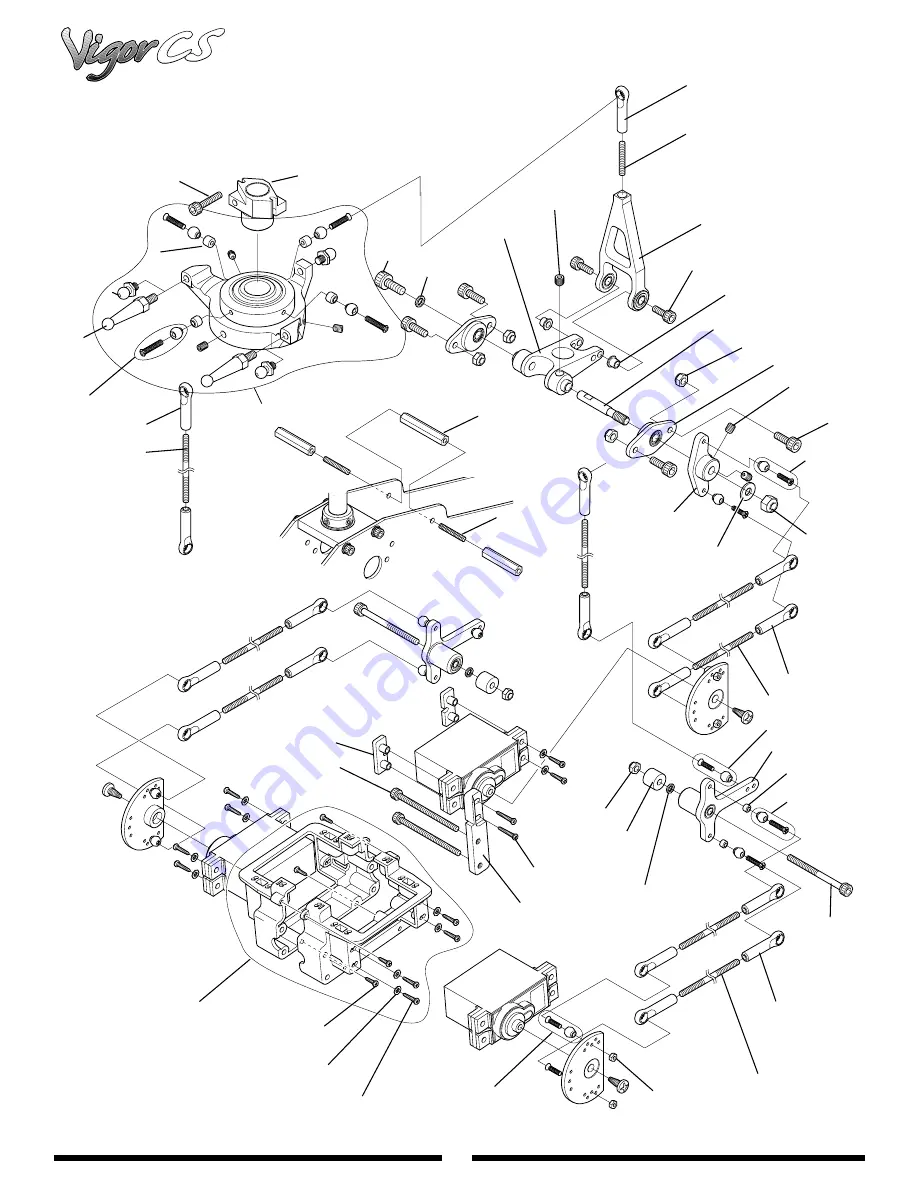

SWASHPLATE/CCPM CONTROL SYSTEM

™

Summary of Contents for Vigor CS

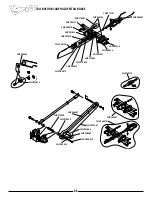

Page 64: ...64 E A C D G F DECAL PLACEMENT ...

Page 65: ...65 B 3 2 5 1 DECAL PLACEMENT ...