KIROVETS K-744R1, K-744R2, K-744R3, K-744R4 tractors

158

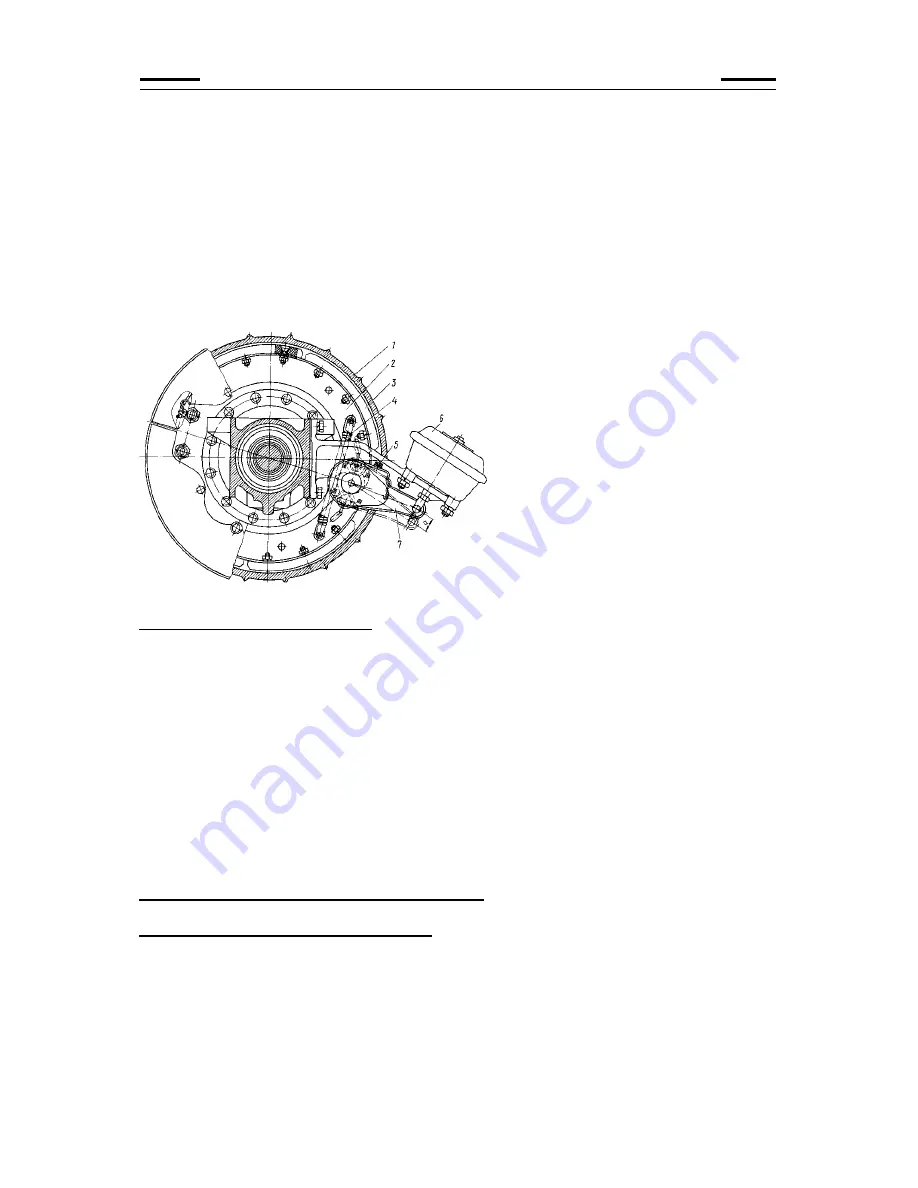

b) Depress the brake pedal and check the travel of brake chamber stems 6 (Fig. 44).

Stem travel shall be within 30-45 mm, travel difference between the right-hand and

left-hand stems shall not exceed 7 mm.

If necessary, perform the following adjustment: rotate axle 5 to reach the travel value of 30-

45 mm, rotate the worm each time at 1/6 of turn (60°) to the next fixed position. Thereafter

check the tractor in driving.

Make sure of reliable and simultaneous action of brakes, absence of heating of brake drums

1 when the tractor drives without using brakes.

7.5.7 Cardan shaft maintenance

In the process of operation observe the following rules of maintenance for cardan shafts:

a) at the end of each shift check by touch the degree of heating of bearing assem-

blies (if it’s not too hot – the heating is normal). In case of overheating, take off the

cardan shaft. Eliminate faults at TSS or in a workshop. In case of removal of cardan

shafts from the tractor or their installation on the tractor, one cannot use tyre iron or

any other items to be inserted into the joint for cardan shaft barring. This entails a

damage of seals, which can lead to premature failure of cardan joints;

b) systematically check fastening of cardan joint flanges. All nuts shall be reliably

tightened;

7.5.8 Maintenance of tractor pneumatic system

Condensate drainage from air cylinders

In order to ensure normal operation of the pneumatic drive, remove condensate from air cyl-

inders after the completion of work, as condensate may get into tubes and instruments of the

braking system and lead to their failure.

Fig. 44 Service brake

1 - brake drum; 2 - brake shoe; 3 - pad;

4 - spring; 5 - worm axle;

6 - brake chamber; 7 - brake lever;

a - brake chamber stem travel