KIROVETS K-744R1, K-744R2, K-744R3, K-744R4 tractors

160

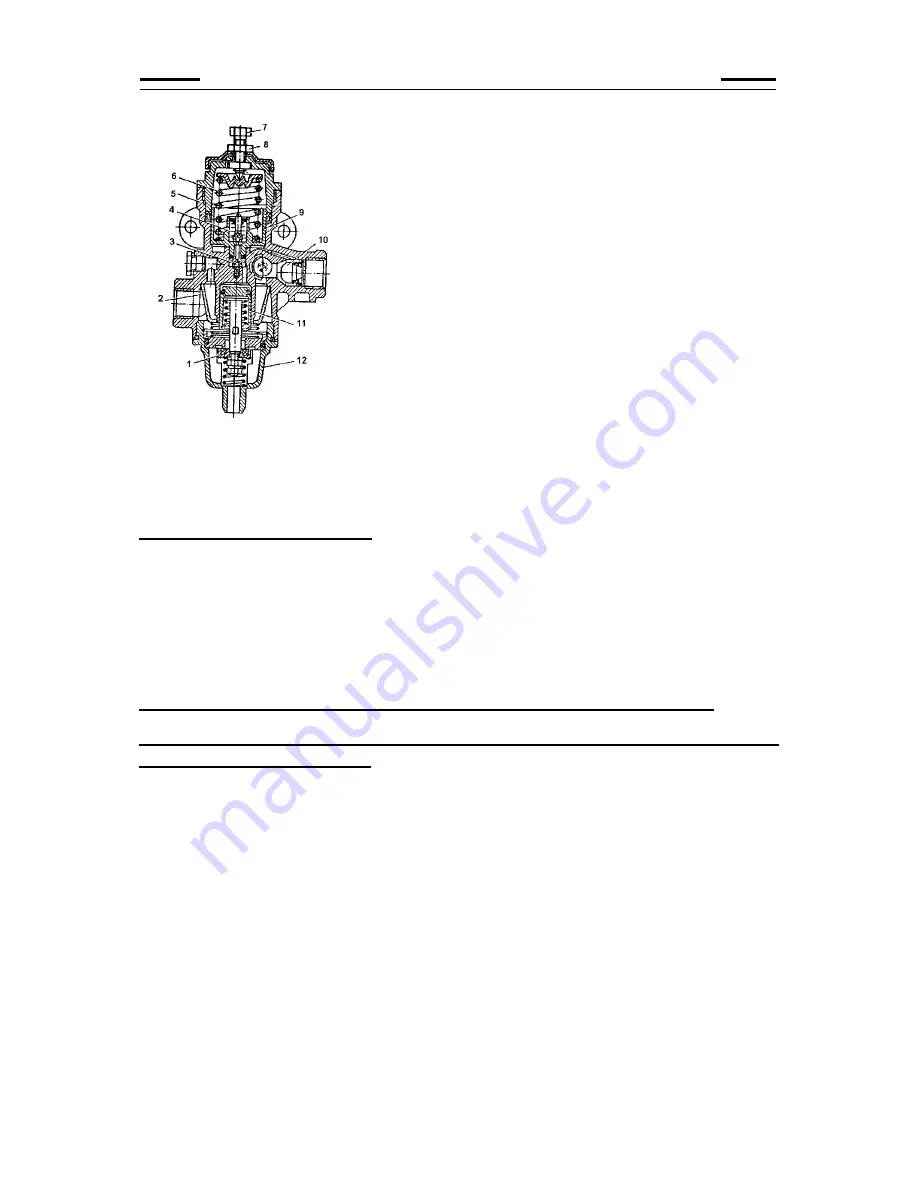

In order to clean the filter, undo cover 12 and carefully take it off along with pressure relief

piston 11 and filter 2. Wash the filter in benzine and blow it down with compressed air. Per-

form the assembly in the reverse order.

Brake system unit maintenance

Taps and valves do not need any special maintenance. Replace taps in case of any defects

detected in the course of operation.

Maintenance of connecting heads consists of systematic inspection, cleaning from dirt. Con-

necting heads are closed with covers protecting them against the ingress of dirt, snow, mois-

ture.

7.5.9 Maintenance of hydraulic systems of the linkage and for steering control

Level check and change of oil in the hydraulic tank of the hydraulic systems of the

linkage and for steering control

Put the tractor on a horizontal ground.

Check oil level in the hydraulic tank via the sight hole 25 (Fig.46); oil should be visible

through the sight hole. Fill clean oil through the grill of filler port 7. When checking oil level in

the hydraulic tank, make sure of the absence of foam generation.

Fig. 45 Pressure controller

1

– pressure relief valve; 2 – filter; 3 – inlet valve;

4

– outlet valve; 5 – housing; 6 – spring;

7

– adjustment bolt; 8 – locking nut;

9

– servo piston; 10 – check valve;

11

– pressure relief piston; 12 – cover