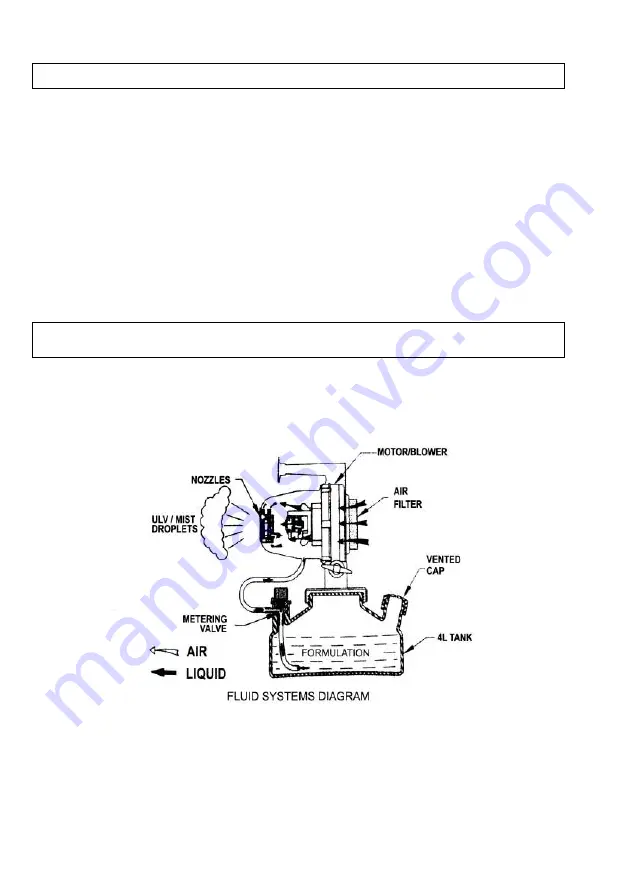

Working Principles

The Machine consist of a motor/blower assembly, a nozzle system, nozzles housing, a formulation

tank and a metering valve.The various components are identified in a digramm below.The blower

is a single stage/centrifugal impeller/axial flow driven by a universal motor operating at a speed of

about 20.000 rpm.The blower moves a large amount of air through the noozle system consisting of

three individual noozles, each of which has two sets of directing vanes. One vane set causes the air

to be rotated clockwise and the other causes forces shears the material being dispensed into small

particles.Further the air rushing by the specially shaped liquid tubes creates a negative pressure in

the liquid tube. This negative pressure causes the liquid to the drawn from the formulation tank

through the control valve and into the nozzle system where it is pneumatically sheared into aerosol

or mist size droplets.After breack-up, the droplets are driven away from the machine by the air

passing through the noozle system.

Generally, the size of the output droplets increases with increasing flow rate and

with increasing viscosity.

-3-

Summary of Contents for Cold Fog

Page 1: ...JSR Fogger...