675

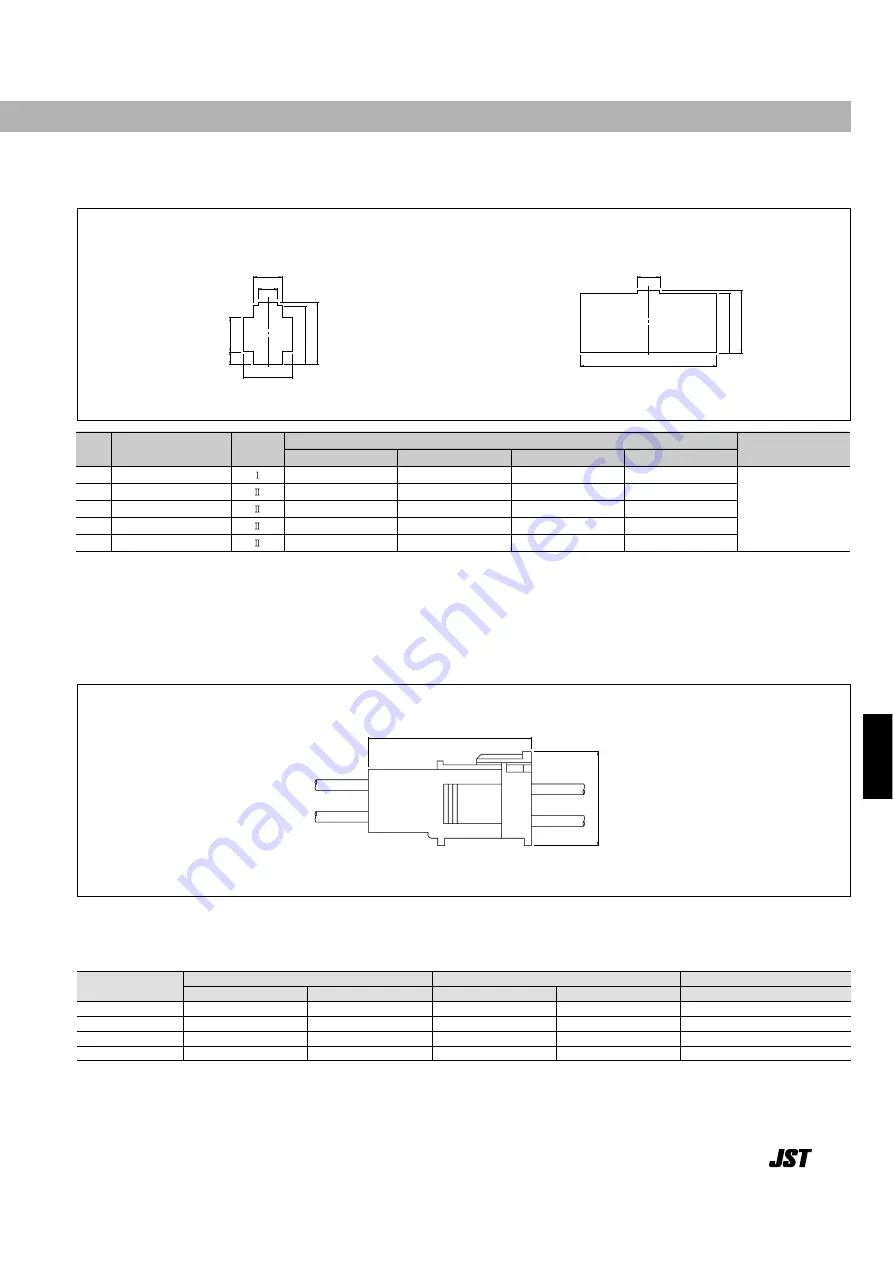

Panel layout––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Shape l

Shape ll

Note:

1. Punch holes in the panel according to the sketch and table shown above. Burrs must be removed.

2. The strength of the panel must be considered when punching two or more holes.

3. The connector must be inserted from the same side as the hole is punched.

6.5

(.256)

B

7.8

(.307)

2.7

(.106)

A

D

C

B

D

C

A

Cir-

cuits

Receptacle

housing

Panel dimensions mm(in.) General tolerance

±

0.13(

±

.005)

A

B

C

D

Applicable panel

thickness mm(in.)

Panel

hole

shape

2

4

8

12

16

XLR-02V

XLR-04V

XLR-08V

XLR-12V

XLR-16V

11.5( .453)

16.5( .650)

26.5(1.043)

36.5(1.437)

46.5(1.831)

4.4(.173)

5.2(.205)

5.2(.205)

5.2(.205)

5.2(.205)

13.95(.549)

13.95(.549)

13.95(.549)

13.95(.549)

13.95(.549)

13.2(.520)

13.2(.520)

13.2(.520)

13.2(.520)

13.2(.520)

0.7 to 2.4

(.028 to .094)

Assembly layout––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

30.9(1.217)

17.7(.697)

XL

CONNECTOR

Contact

Crimp applicator MKS-L

Compact crimp applicator MKS-LS

Strip-crimp applicator MKS-SC

with safety cover

without safety cover

with safety cover

without safety cover

with safety cover

Applicator for the semi-automatic press AP-K2N –––––––––––––––––––––––––––––––

SXF-01T-P0.7

APLMK SXF01-07

APLNC SXF01-07

–

–

–

SXF-41T-P0.7

APLMK SXF41-07

APLNC SXF41-07

–

–

APLSC SXF41-07

SYM-01T-P0.7

APLMK SYM01-07

APLNC SYM01-07

–

–

–

SYM-41T-P0.7

APLMK SYM41-07

APLNC SYM41-07

–

–

–