16

4.4. Electronic controller EVCO

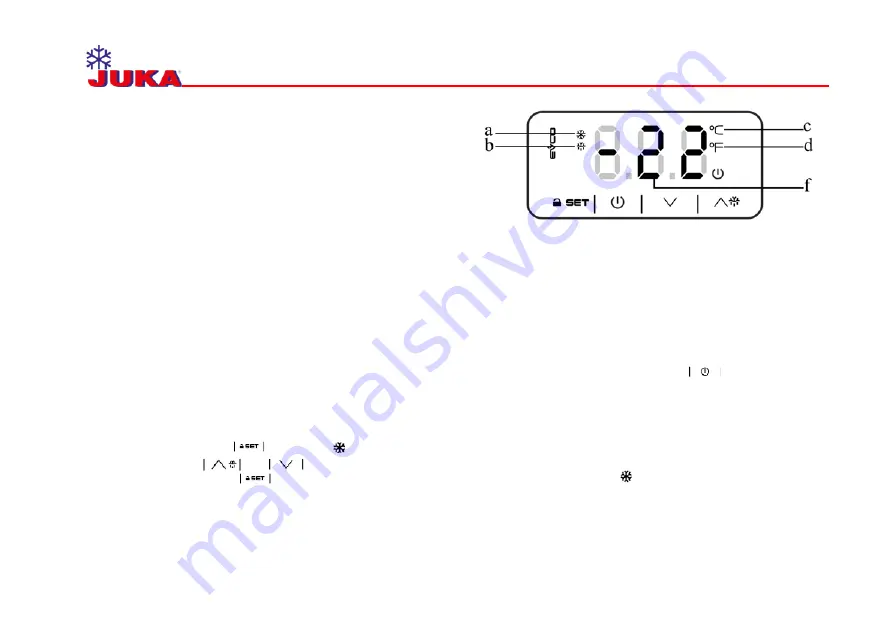

4.4.1. Light Signals on the Electronic Controller`s Display:

Diode а –

Compressor

:

The symbol is visible during operation of

the compressor. It is blinking when modification process is ongoing or

in case when compressor operation is protected by security procedure.

Diode b –

Defrosting

: the symbol is visible when the defrosting

function is turned on. It is blinking when defrosting start is delayed

by external disengagement or when another procedure is in progress.

Diode c –

Celsius

temperature scale

. The symbol is visible when

temperature is set in degrees Celsuis.

Diode d –

Fahrenheit temperature scale

. The symbol is visible when temperature is set in degrees Fahrenheit.

Diode f –

temperature inside

the cabinet.

During operation the display of the controller shows the actual temperature inside the equipment.

• Locking/unlocking of the controller keypad

The controller keypad is automatically locked in 30 seconds after the last pressure of the button - the

«Loc»

code is displayed for 1

second. To unlock press any button while holding it for 4 seconds -

«UnL»

code will be displayed for 4 seconds.

• Turning on/off of the equipment

Ensure that the keypad is not locked, unlock if necessary. To turn the equipment on/off press the button and

hold for 4 seconds -

the indicator will blink, after this the equipment will be switched on / off.

When voltage is supplied, the red switch must light up (switch is equipped with light diodes, so when the voltage is supplied, it must light up).

4.4.2. Setting of the Temperature

• make sure the keypad is not locked, unlock if necessary

• briefly press the button

, indicator (

) will start to blink;

• using the buttons

and

set the required tempera;

• briefly press the button

to confirm or do nothing within 15 seconds - the indicator (

) will stop blinking, the controller

completes the setup process (all changes will be saved).

4.4.3. Warning Signals

„Pr1”

- malfunction of temperature sensor

„Pr2”

- malfunction of defrost sensor

„СOH”

- warning signal indicating that condenser is dirt and overheated;

„dFd”

- defrosting process is finished.

Picture 15. Electronic controller EVCO