– 4 –

SPECIFICATIONS

○

Presser foot lifting amount : Standard 9mm.

○

Max. presser foot pressure : 88N.

* Line voltage : At 100%

11.

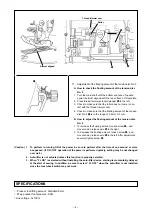

Adjustment of the floating amount of the tension disc No. 2.

A.

How to check the floating amount of the tension disc

No. 2

1. Turn the main shaft until the bottom end face of needle

eyelet is almost aligned with the top surface of throat plate.

2. Press thread trimmer solenoid plunger

to the left.

3. Check to make sure that the roller does not come in con-

tact with the thread trimmer cam.

4. Check to make sure that the floating amount of the tension

disc No. 2

is in the range of 0.5 mm to 1 mm.

B.

How to adjust the floating amount of the tension disc

No. 2

1. To increase the floating amount, loosen screw

, and

move tension release wire

to the right.

2. To decrease the floating amount, loosen screw

, and

move tension release wire

to the left. After adjustment,

securely tighten screw

.

(Caution) 1. To perform re-turning ON of the power, be sure to perform after the time of one second or more

has passed. (If ON / OFF operation of the power is performed quickly, setting may be not changed

over well.)

2. Auto-lifter is not actuated unless this function is properly selected.

3. When “FL ON” is selected without installing the auto-lifter device, starting is momentarily delayed

at the start of sewing. In addition, be sure to select “FL OFF” when the auto-lifter is not installed

since the touch-back switch may not work.

Almost aligned

Thread trimmer cam

Roller

Summary of Contents for AK85C

Page 1: ...AK85C INSTRUCTION MANUAL ...