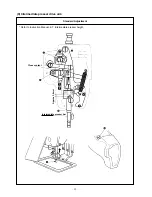

1. Insert the main shaft

into the crank rod

, balancer

, hand pulley gear A

, bobbin winding drive

wheel

, and main shaft counterbalance

in this order, and mount this assembly on the frame.

2. Tighten the taper screw

into the taper hole of the main shaft

, and tighten the set screw

to secure

the main shaft counterbalance

.

3. Lightly press the main shaft counterbalance

in the direction of Arrow D and the middle metal

in the

direction of Arrow E, and tighten 2 set screws

.

(Tighten No. 1 set screw so that it touches the flat part of the main shaft

. Then, tighten No. 2 set screw.

Same procedure hereafter)

4. Tighten 2 set screws

and 2 set screws

. (Make sure that No. 1 set screw touches the flat part of the

main shaft

.)

5. Press the hand pulley

in the direction of Arrow F to engage the hand pulley gear A

with the hand pulley

gear B

, and secure them with 2 set screws

.

6. Mount the main shaft motor

and coupling

.

Refer to “3.-(2) Removal of main shaft motor and coupling”.

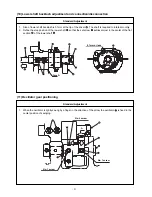

7. Secure the eccentric cam of the intermediate presser

with 2 set screws

. Refer to “3.-(5) Adjustment

of intermediate presser cam”.

8. Secure the crank rod

with 2 set screws

. Refer to “3.-(3) Crank rod connection/disconnection”.

9. Secure the balancer

with 2 set screws

. Refer to “3.-(4) Crank balancer positioning”.

10. Secure the bobbin winding drive wheel

with 2 set screws

. Refer to “3.-(34) Adjustment of the bobbin

winder driveing wheel poition”.

* Make sure that no torque is applied by rotating the main shaft

.

– 6 –

Procedures of assembling