P 1

P 2

P 3

P 4

P 5

– 143 –

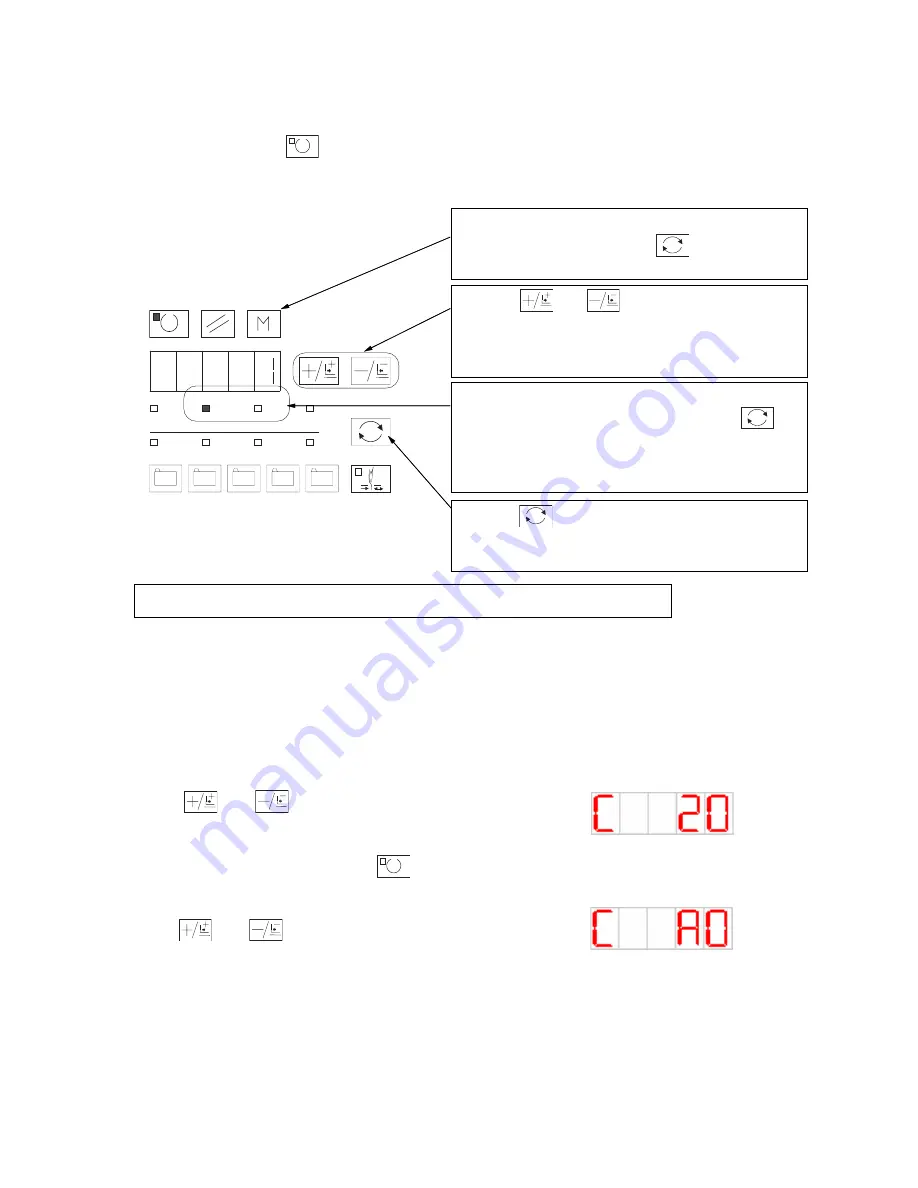

2) CP-2 (XY motor / origin sensor check)

The status of inching operation of the X/Y motor, operation of origin retrieval, and the X/Y origin sensors is

displayed.

1. In the first place, press the key to carry out needle thread clamping and origin retrieval for the presser and

thread trimmer motor. The presser assumes the lowering condition.

After the completion of preparation, the sewing LED is lit.

2. Operation

3) CP-3 (Continuous operation)

After the conditions of continuous operation have been set, the opera-

tional mode moves to the continuous operation mode.

To cancel the continuous operation mode, it is necessary to turn the

power supply OFF.

1. Rest time setting

Press the and keys to set up the rest time.

Setting is possible within the range of 0 to 9900ms in the unit of 100ms.

(Initial value 2000ms)

After the completion of setting, press the key.

2. Setting for the presence of origin retrieval at the end of sewing

Press the and keys to set up the presence of origin retrieval

at the end of sewing.

A0: Ineffective (Initial value)

A1: Every 100 sewing cycles

A2: Every sewing cycle

Using the Start SW, origin retrieval of the X/Y motors is effected for both shafts.

According to the status of the selected X/Y origin sen-

sor, “0” or “1” is displayed. The key is pressed to

make changeover.

Using the and keys, drive the selected X/Y

motor in the direction of +/– by 0.1mm each time.

(Caution) Since the circular interpolation system is

used, any motor not selected is also driven.

The selection status of the X motor (X origin sensor) or

the Y motor (Y origin sensor) is displayed. The key

is pressed to make changeover.

X enlargement/reduction scale rate LED lit: X motor (X

origin sensor)

Using the key, the selection status of the X motor

(X origin sensor) or the Y motor (Y origin sensor) is

changed over.