– 16 –

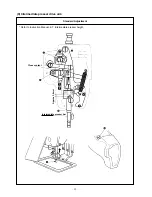

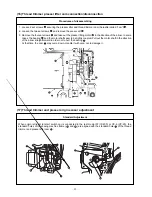

Procedures of assembling

1. Fix the intermediate presser variable shaft

to the intermediate presser variable arm

by means of the

two setscrews

so that the length of the shaft section becomes 193.8mm.

(Both setscrews

should be adjusted level to the intermediate presser variable shaft

.)

2. Insert the washer

, thrust bearing

, thrust collar

, and the drive bevel gear

in the intermediate

presser variable shaft

in this order, and mount this assembly on the frame.

3. Pressing the intermediate presser variable arm

in the direction of the Arrow E, secure a proper thrust by

pressing the thrust collar

in the direction of the Arrow D and tighten the two setscrews

. (Tighten the

first screw first so that it is fixed level to the intermediate presser variable shaft

. Then, tighten the second

screw. To be done in the same manner hereafter.)

(Caution) If there is rattle in the variable shaft of the intermediate presser

in the forward and back-

ward directions, this can be a cause of intermediate presser step-out. Be careful when you try

to fix the thrust collar

.

4. Adjust the distance to 4.4mm between the thrust collar

and the drive bevel gear

. Tighten the first

screw of the setscrew

.

(Tentatively tightened till the completion of intermediate presser sensor adjustments)

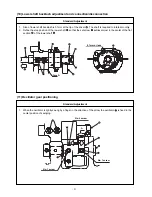

5. Fix the intermediate presser motor

to the intermediate presser motor mounting plate

and mount the

intermediate presser coupling

on the motor shaft. Since then, press the intermediate presser motor

assembly in the direction of the Arrow F and tentatively fix it to the frame by means of the two setscrews

.

Adjust the positioning of the intermediate presser motor assembly where the intermediate presser coupling

) can be turned without any resistance, and tighten the two setscrews

.

6. Insert the sensor slit

, intermediate presser lifting cam

, thrust collar

, and the wave washer

in the

intermediate presser lifting shaft

in this order, and pass this assembly through the frame. Mount the E

ring

on the intermediate presser lifting shaft

.

7. Pressing the intermediate presser lifting shaft

in the direction of the Arrow C, press the thrust collar

in

the direction of the Arrow G and tighten the two setscrews

.

8. Fix the intermediate presser lifting cam

by means of the two setscrews

so that the clearance becomes

0.5mm between both end planes of the intermediate presser lifting cam

and the intermediate presser

lifting link

.

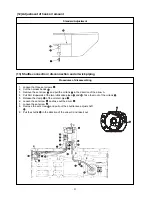

9. Turn the intermediate presser variable shaft

and the intermediate presser lifting shaft

so that the

trailing bevel gear

and the drive bevel gear

are positioned as shown in Fig. J. Since then, fix them by

means of the two setscrews

while the trailing bevel gear

is pressed in the direction of the Arrow G (in

order to reduce the backlash to zero).

10. Press the sensor slit

in the direction of the Arrow C and turn the setscrew

so that its H comes in the

section toward the setscrew

of the intermediate presser lifting cam

. Then, fix H of the setscrew

tentatively.

11. According to adjustments of intermediate presser variable as described in 3-(8), make adjustments of inter-

mediate presser variable and fasten the setscrews of the drive bevel gear

and the sensor slit

.

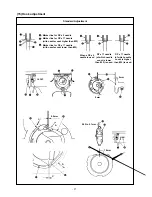

12. Using the step screw

, mount the intermediate presser variable link

on the intermediate presser vari-

able arm

.

13. Using the step screw

, mount the intermediate presser variable plate

and the variable plate spacer

.

14. Mount the step screws

,

, and

.

15. Using the step screw

, mount the intermediate presser variable link

on the intermediate presser vari-

able plate

.

16. Mount the intermediate presser auxiliary spring

.

17. Mount the intermediate presser spring

and the guide shaft from above the frame. Then, mount the

presser adjusting screw

.

(27.0mm from the upper plane of the arm to that of the presser adjusting screw

)