– 208 –

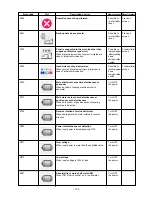

1. Sewing machine locked

1-1) Large needle compared with

Replace the needle hole guide.

the hole diameter of the needle

hole guide

2. Deformation in sewn patterns

2-1) X timing belt tension is

Adjust the X timing belt tension.

maladjusted.

2-2) Backlash of the X feed motor

Adjust the position of X feed motor.

gear is maladjusted.

2-3) Backlash of the Y feed motor

Adjust the position of Y feed motor.

gear is maladjusted.

2-4) Traveling torque in X direction

4-A) Pressure of the X-Y table is

Adjust the pressure of the X-Y table.

or Y direction is excessive.

too high.

4-B) Height or horizontality is

Adjust the height or the horizontality of the needle

inadequate for the needle bar

bar auxiliary cover.

auxiliary cover.

2-5) Pressing pressure is too low.

5-A)Regulator is maladjusted.

Adjust the regulator.

(Air specification)

5-B) Supply air pressure is too low.

Adjust the supply air pressure.

3. There is no coincidence between

3-1) Inadequate adjustment of the

Adjust the position of X origin sensor.

the input origin and the sewing origin.

X origin sensor

3-2) Inadequate adjustment of the

Adjust the position of Y origin sensor.

Y origin sensor

4 Feeding action does not stop even

4-1) Inadequate adjustment of the

Adjust the position of X origin sensor.

after exceeding the sewing range.

X origin sensor

4-2) Inadequate adjustment of the

Adjust the position of Y origin sensor.

Y origin sensor

5. The amount of lifting is small for the

5-1) Inadequate adjustment of the

Adjust the height of the presser.

outer frame of the cloth presser.

height of the presser

Trouble

Cause (1)

Cause (2)

Check and corrective measures

13. Troubles and corrective measures

(1) Mechanical parts