– 209 –

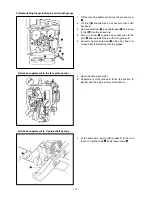

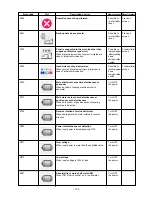

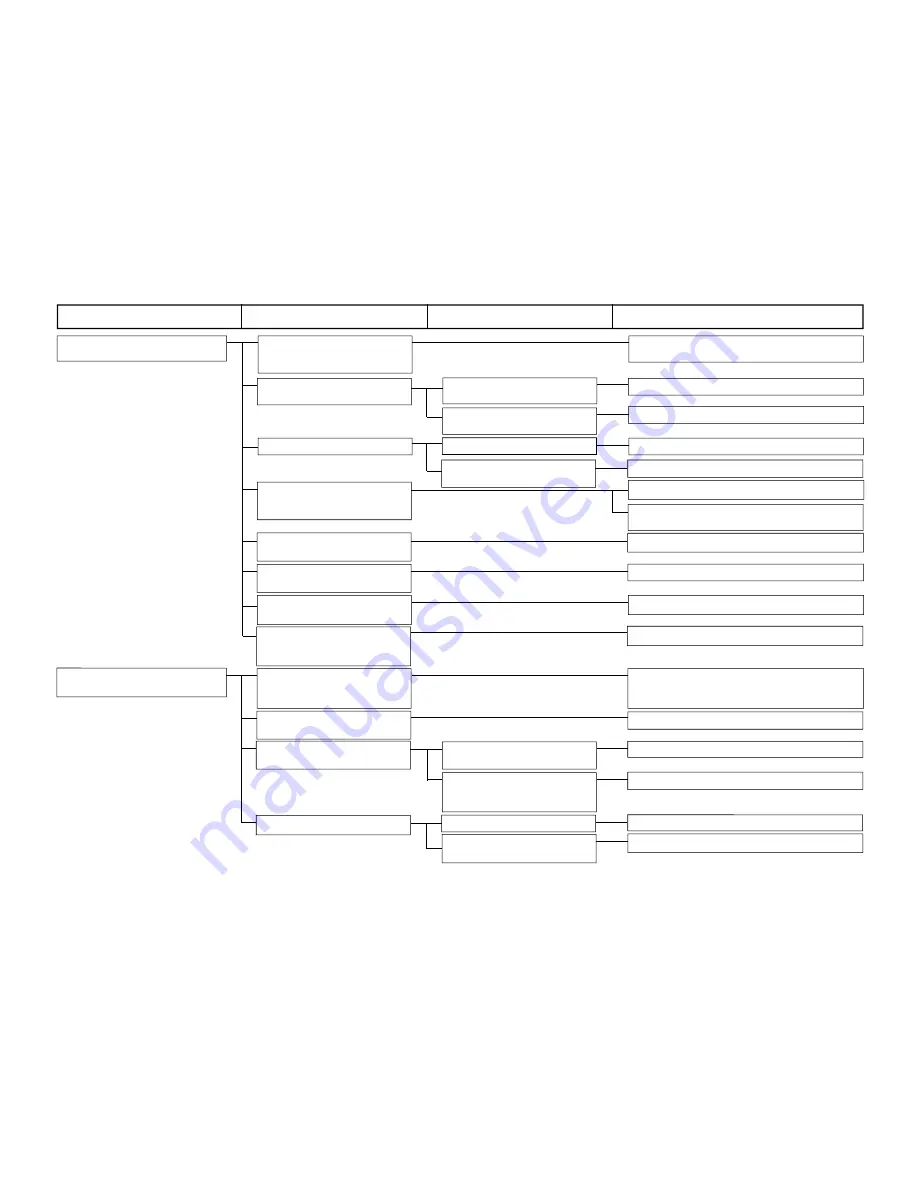

6. The outer frame of the cloth presser

6-1) The thread trimmer cam

Decide the position of the thread trimmer cam screw

cannot be lifted or lowered.

screw is loose.

and fix it.

(Motor specification only)

6-2) Presser pulse motor malfunction

2-A) The presser pulse motor is

Replace the presser pulse motor.

(motor specifications only)

out of order.

2-B) Connection of presser pulse

Check the connector connections.

motor is improper.

6-3) Defective board

3-A) The board is out of order.

Replace the board.

3-B) Connector connections are

Check the connector connections.

improper.

6-4) There are inadequate fitting

Examine the positions for greasing.

conditions among the work feed

bar, the link, and the face plate.

The sewing material is not pressed completely by the

outer frame as a whole.

6-5) Supply air pressure is too low.

Adjust the supply air pressure.

(Air specification only)

6-6) Inadequate adjustment of the

Adjust the regulator.

regulator (air specifications only)

6-7) Solenoid valve malfunction

Reolace the solenoid valve.

(air specifications only

6-8) Inadequate adjustment of the

Adjust the speed controller.

speed controller

(air specifications only)

7. The intermediate presser does not

7-1) There are some inadequate

Check for the inadequate fitting and rattling conditions

rise after sewing.

fitting conditions in the intermedi

in the link mechanism.

ate presser link mechanism.

Examine the positions for greasing.

7-2) Intermediate presser variable

Adjust the intermediate presser variable.

is maladjusted.

7-3) Intermediate presser pulse

3-A) Intermediate presser pulse

Replace the intermediate presser pulse motor.

motor malfunction

motor is out of order.

3-B) Connection of intermediate

Check the connector connections.

presser pulse motor is

improper.

7-4) Defective board

4-A) The board is out of order.

Replace the board.

4-B) Connector connections are

Check the connector connections.

improper.

Trouble

Cause (1)

Cause (2)

Check and corrective measures