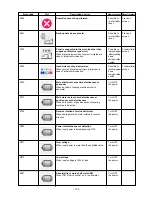

– 211 –

10. Even when the sewing machine is

10-1) The needle thread is not

Pass the needle thread.

started, it goes to stop soon.

hooked.

10-2) Position of the thread breakage

Adjust the position of the thread breakage detecting

detecting plate is wrong.

plate.

11. Even though the needle thread is

11-1) Position of the thread

Adjust the position of the thread breakage detecting

broken, the sewing machine does

breakage detecting plate is

plate.

not stop.

wrong.

12. Wiper cannot spread a thread

12-1) Interference between wiper

1-A) Wiper mounting position is

Adjust the wiper position.

and needle

inadequate.

12-2) Interference between wiper

2-A) Inadequate adjustment of the

Adjust the height of the intermediate presser.

and intermediate presser

height of the intermediate

presser

2-B) Wiper mounting position is

Adjust the wiper position.

inadequate.

12-3) There is no clearance between

3-A) The cloth thickness permitting

Use the lower wipe-out sequence.

the needle and intermediate

the use of a wiper is exceeded.

presser to pass the wiper.

12-4) The wiper does not move

4-A) The wiper switch is turned

Turn the wiper switch ON.

after thread trimming.

OFF.

13. Severe vibration

13-1) Position of the crank balancer

Define the correct crank balancer position.

is wrong.

Trouble

Cause (1)

Cause (2)

Check and corrective measures