– 18 –

Adjustment Procedures

Results of Improper Adjustment

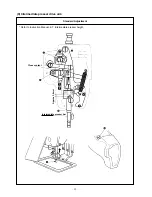

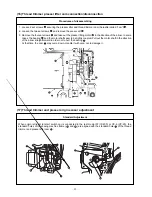

1. Start the Test Mode I10 (IP-400) or CP-8 (CP-20).

2. Tread on the start pedal for origin retrieval, and make adjustments by

turning the sensor slit

so that the lines combining the center of the

intermediate presser lifting shaft

, the standard hole of the interme-

diate presser lifting cam

, and the center of the cam follower

become almost a straight line.

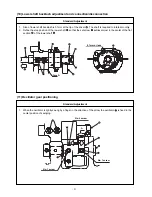

3. Press of the panel three times. Loosen the first screw

of the

drive bevel gear

of the intermediate presser variable shaft

.

Take out the drive bevel gear

from the flat part of the intermediate

presser variable shaft

and move it in the direction of the Arrow A.

4. Using the [+] key or the [–] key, turn the intermediate presser variable

shaft

until the second screw

of the intermediate presser vari-

able arm

settles in the center of the arm’s left-side hole C. (Insert

a hexagonal wrench to adjust positioning so that the arm comes in

the center of backlash deflection.)

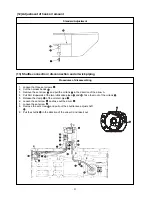

5. Turn the intermediate presser lifting shaft

so that the second screw

of the intermediate presser lifting cam

comes just above. Press

the drive bevel gear

of the intermediate presser variable shaft

in the direction of the Arrow B to fix it.

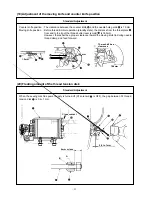

6. After the completion of second origin retrieval, press of the

panel twice to secure the [timing adjustment position]. In this case,

confirm that the second screw

of the intermediate presser vari-

able arm

is positioned in the center of the arm’s left-side hole C or

below it. (If the screw seems to have been positioned above the cen-

ter, return to Step 4 and repeat the above-mentioned adjustments.)

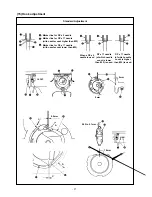

7. If the second screw

of the intermediate presser variable arm

is

not positioned in the center (or lower), loosen the setscrew

of the

sensor slit

and turn this sensor slit

in the direction of the Arrow

A for fine adjustments.

8. Make origin retrieval and confirm that the the cam follower

is lo-

cated in the parallel section of the intermediate presser lifting cam

. When the condition has been found normal, fasten the setscrew

of the drive bevel gear

and the setscrew

of the sensor slit

regularly.

(Caution) For the prevention of the sensor

from destruction,

make origin retrieval after confirming that the slit of the

sensor slit

is positioned in the center of the sensor

.

o There will be a displacement

between the variable value of the

i n t e r m e d i a t e p r e s s e r l o w e r

position and the panel setup

value.

o If there is no cam follower

in

the parallel section of the interme-

diate presser lifting cam

at the

time of origin retrieval, stepping

out may occur in the intermediate

presser motor, thus causing de-

fective stitches, generation of

sound from the face plate section,

and destruction of parts.

o If adjustments of backlash are in-

sufficient for the drive bevel gear

, stepping out may occur in the

intermediate presser motor, thus

causing defective stitches, gen-

eration of sound from the face

plate section, and destruction of

parts. .