– 226 –

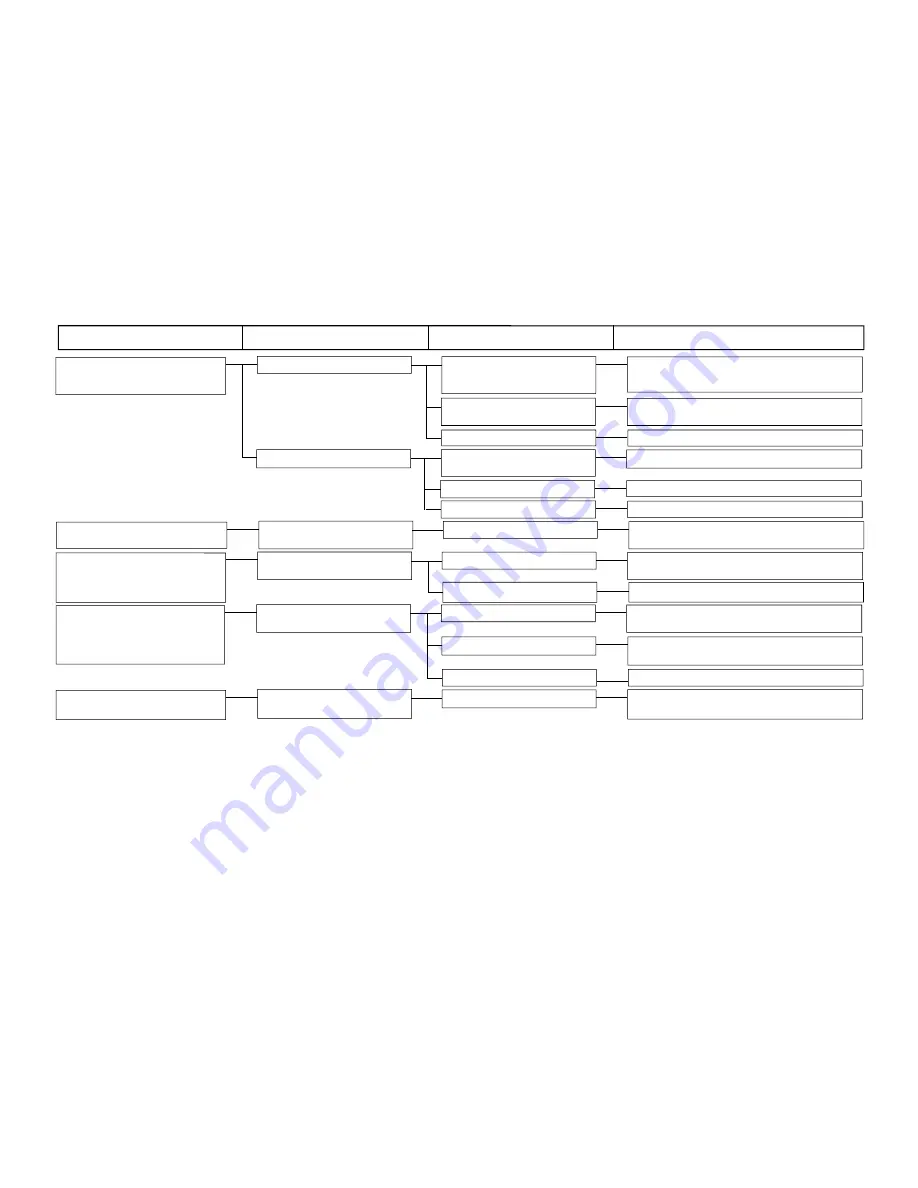

26. Error E913

26-1)Irregular motor rotations

1-A) There are irregularities in the

Check the mechanism and look for the section that

Needle thread clamp origin

mechanism, such as

is particularly overloaded, that is any holdup or

retrieval error

overloading, etc.

whether screws are loose.

1-B) Motor leads are broken.

Check the resistance of the motor winding.

The motor is out of order.

Replace the motor, as required.

1-C) The driver circuit is out of order.

Replace the MAIN board.

26-2)No sensor signal entry

2-A) The sensor is out of order or

Check the sensor with the test program I_03 or I_08.

broken.

2-B) Connector connection defective

Check CN65 of INT board.

2-C) Input circuit is out of order.

Replace the MAIN board.

27. Error E914

27-1)Irregular main shaft motor

1-A) Motor revolutions are unstable.

Check whether coupling for connection of main shaft

Feed trouble error

rotations

and motor is loose.

28. Error E915

28-1)Data cannot be received

1-A) MAIN board fails to work.

All the dip switches of the MAIN board shall be set

Communication error between

from the MAIN board.

at OFF.

the PANEL and MAIN boards LED1

on MAIN board: Flashing 1 times

1-B) Board defective

Replace the MAIN board or PANEL board.

29. Error E916

29-1)Data cannot be received

1-A) MAIN board fails to work.

All the dip switches of the MAIN board shall be set

Communication error between

from the SDC board.

at OFF.

the SDC and MAIN boards

LED3 on SDC board: Flashing

1-B) SDC board fails to work.

All the dip switches (SW2) of the SDC board shall be

15 times

be set at OFF.

1-C) Board defective

Replace the MAIN board or SDC board.

30. Error E918

30-1)The heat sink for the power

1-A) Cooling is not effective.

Check for any clogging at the suction port or

MAIN board overheat

supply has exceeded 85

°

C.

examine the conditions in the fan, etc.

Trouble

Cause (1)

Cause (2)

Check and corrective measures